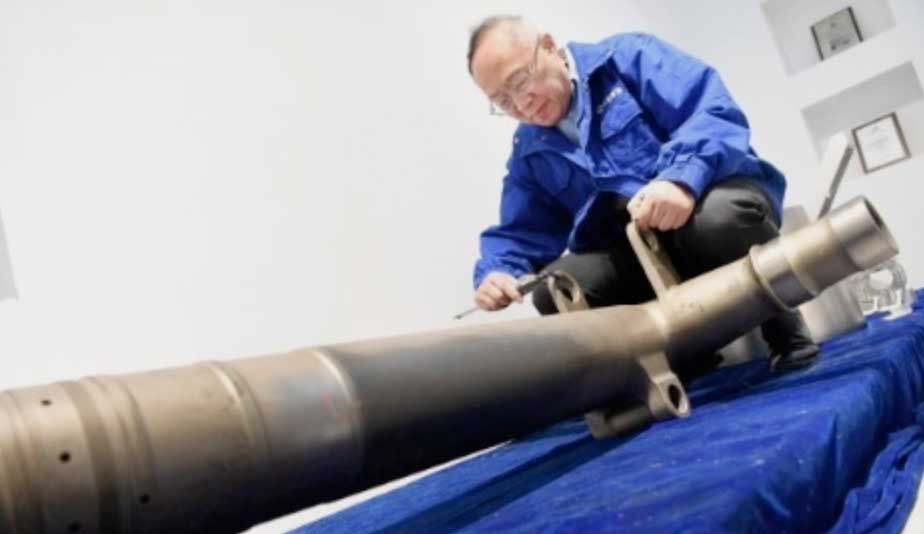

In Wuhan, China, a team of researchers has succeeded in producing the world’s first 3D-printed “piston rod axle” for aircraft landing gear.

The solid metal T-shaped component measures 1.5 meters in length, weighs 240 kilograms and is visually indistinguishable from conventionally manufactured counterparts. The challenge was to avoid the cracks that often occur in 3D printing processes.

Professor Zhang Haiou and his team at Huazhong University solved this problem in 2019 with a new type of 3D printing machine that combines the casting, forging and milling processes in a single operation. This overcomes the limitations of conventional methods.

The advantages are considerable: according to Prof. Haiou, 90% of the material is saved compared to traditional production, resulting in significant cost and environmental benefits. In addition, the 3D-printed components are even more robust than conventionally manufactured ones after thorough testing.

This project marks a milestone, as only a few countries are currently able to produce large aircraft landing gear. Wuhan Tianyu Intelligent Manufacturing is the world’s first manufacturer to produce such a critical component using 3D printing.

Wuhan Tianyu is a leading provider of 3D printing and works with industry giants. In the long term, the innovation could revolutionize aircraft manufacturing and enable more cost-effective and environmentally friendly production processes. However, the safety of 3D-printed aircraft still needs to be convincingly demonstrated before they can be used in scheduled flights.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.