The United States Navy wants to massively increase the number of parts produced using metal additive manufacturing that are used on submarines this year.

The aim is to increase the number of parts from just a few at present to almost 100 by the end of the year. This was stated by Matt Sermon, Executive Director of Strategic Submarines, at the Navy League’s Sea-Air-Space conference.

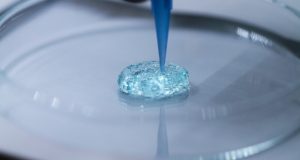

A striking example of AM’s efficiency gains was recently provided when a team of government and industry partners produced a replacement part for a ballistic missile submarine valve that had previously been removed from other systems six times during maintenance phases. Using an accelerated process, the team was able to scan, print, install and test the valve in just nine weeks. By comparison, the traditional supply system would have taken 23 to 24 months.

Currently, the Navy focuses primarily on AM processes for low-weight components – parts that are not exposed to the enormous pressures underwater or the heat of nuclear reactors. Nevertheless, the continuous development of additive manufacturing technologies across key materials is a core concern for the Navy in order to increase its efficiency and capacity in the long term.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.