London-based tech start-up Kibu has joined forces with Batch.Works and Morrama to launch sustainable 3D-printed headphones for children. The “Kibu Headphones” focus on environmental friendliness, personalization and the involvement of young users.

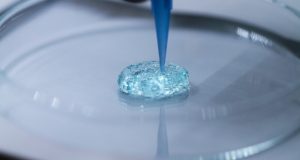

The headphones are made from over 70% recyclable materials, primarily recycled PLA from packaging waste. They are manufactured by Batch.Works using a 3D printing process. This means that Kibu largely avoids the production of new plastics. Kibu also offers a take-back process in which used headphones can be recycled into new ones – exemplary for a circular economy.

Kibu attaches particular importance to safety aspects. The “Kibu Safety Engine” limits the volume to a maximum of 85 decibels to protect children’s sensitive ears. A “Kibu Care” service also provides free spare parts in the event of damage. This significantly increases the service life of the products.

The Kibu headphones are not only impressive in terms of sustainability. Thanks to their modular design, they can be adapted in a variety of ways and assembled in different color combinations. A “daisy chain” function also enables shared listening from one audio source – ideal for use in the classroom or on family outings.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.