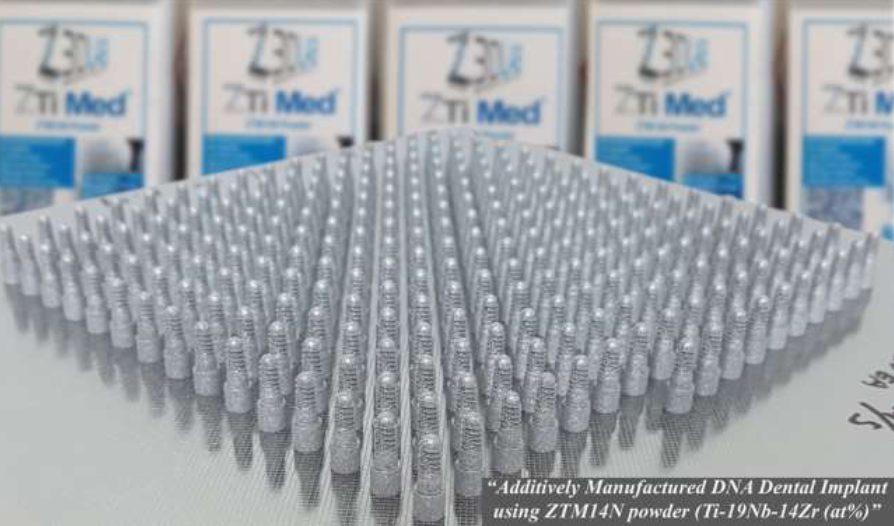

6K Additive and Z3DLab have announced a partnership for the production of advanced ZTi alloys. The agreement is expected to yield new materials for additive manufacturing in the medical implant market and enable future developments in the aerospace industry.

6K Additive will process Z3DLab’s ZTi alloys using its UniMelt technology to produce spherical, dense powders for additive manufacturing.

Dr. Madjid Djemai, President of Z3DLab explained: “Our ZTM14N material is unique for the medical implant industry and has tremendous growth opportunity in the space. However, we cannot afford to suffer the yield loss that is typical in the atomization process during production. We will be burdening the cost unnecessarily for our customers. 6K Additive’s UniMelt delivers the required high yields of highly spherodized powder that enables us to cost-effectively deliver our material to the market. This partnership benefits not only 6K Additive and Z3DLab but also the customers we serve. I am looking forward to our next project in the aerospace sector.”

Z3DLab’s ZTi-Med alloys improve ductility, wear resistance and heat oxidation compared to Ti64 and are ideal for medical implants. In particular, the biocompatible ternary titanium alloy ZTM14N exhibits high resistance to inflammatory species and a Bone Interface Contact (BIC) value of 95%.

Francois Bonjour, European Sales Director for 6K Additive added: “As a company dedicated to sustainability, we believe that the future of AM lies in high-performance alloys that can make lighter, stronger components with longer lifespans. Our UniMelt production scale powder manufacturing platform can process a near-infinite range of alloys thanks to its microwave plasma energy source and unparalleled controllability. It only makes sense for Z3DLab and 6K Additive to partner to bring such an innovative material to the market with the quality and cost model to make it successful commercially.”

6K’s UniMelt process can use waste powder as feedstock, improving the quality of the final powder while creating a circular economy for high-value, high-performance alloys.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.