Brooklyn-based 3D printing startup Arfona and dental materials manufacturer Valplast have collaborated to bring extrusion based 3D printing to the dental industry, introducing the r.Pod desktop 3D printer.

When dental labs turn to 3D printing, models and other appliances are typically printed on resin-based SLA or DLP printers due to their high resolution. However, Arfona CEO Justin Marks believes that FFF 3D printing also offers a number of advantages, such as creating end use parts instead of prototypes and models:

“The ability to create end-use parts is the most exciting feature of the r.Pod® printer. In the past dental thermoplastics had to be either injection molded or vacuum formed, but the possibility to now 3D print them opens up a whole new world of CAD/CAM materials that didn’t exist before. This is particularly interesting for those who work with digital impressions because now there is now a completely digital workflow for restorations like Valplast® that in the past required physical impressions and traditional fabrication techniques.”

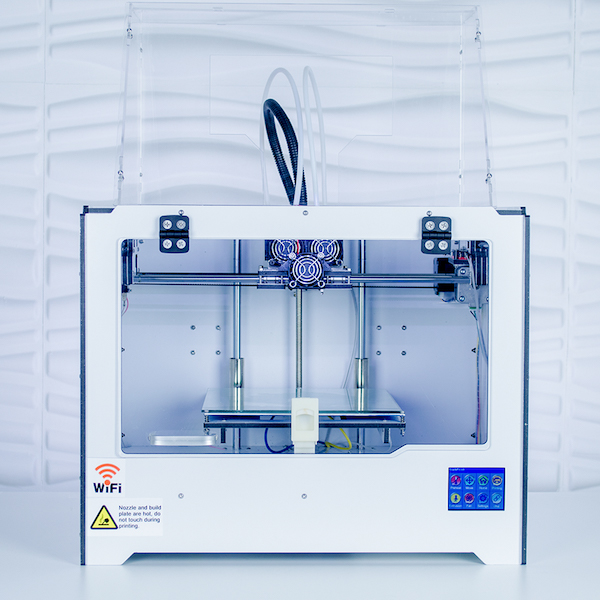

Arfona’s r.Pod FFF 3D printer, that comes with Simplify3D software, is equipped with two nozzles enabling users to print with support material or create multicolour and multimaterial parts. Besides Valplast, the printer is also capable of processing other flexible materials including NinjaFlex and Taulman filaments. Alternatively, the r.Pod is available as single extruder printer, also featuring the Flexion extruder.

Using Valplast dental labs and technicians can 3D print flexible partials that can be combined with custom milled denture teeth.

“We are thrilled that we can now move past the rapid prototyping stage and directly into additive manufacturing for Valplast® appliances,” said CEO Peter Nagy of Valplast International Corp. “Our knowledge of partial denture fabrication coupled with the most cutting edge technology is a slam dunk for labs who wish to go fully digital in their denture department.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.