At the upcoming AMADS event in Bristol, which focuses on additive manufacturing (AM) processes for aerospace, defense and space, Wayland Additive, an OEM for advanced eBeam metal AM systems, will play a significant role. The event will take place on February 27 and 28 and will provide a platform to showcase Wayland’s Calibur3, which is based on the innovative NeuBeam process.

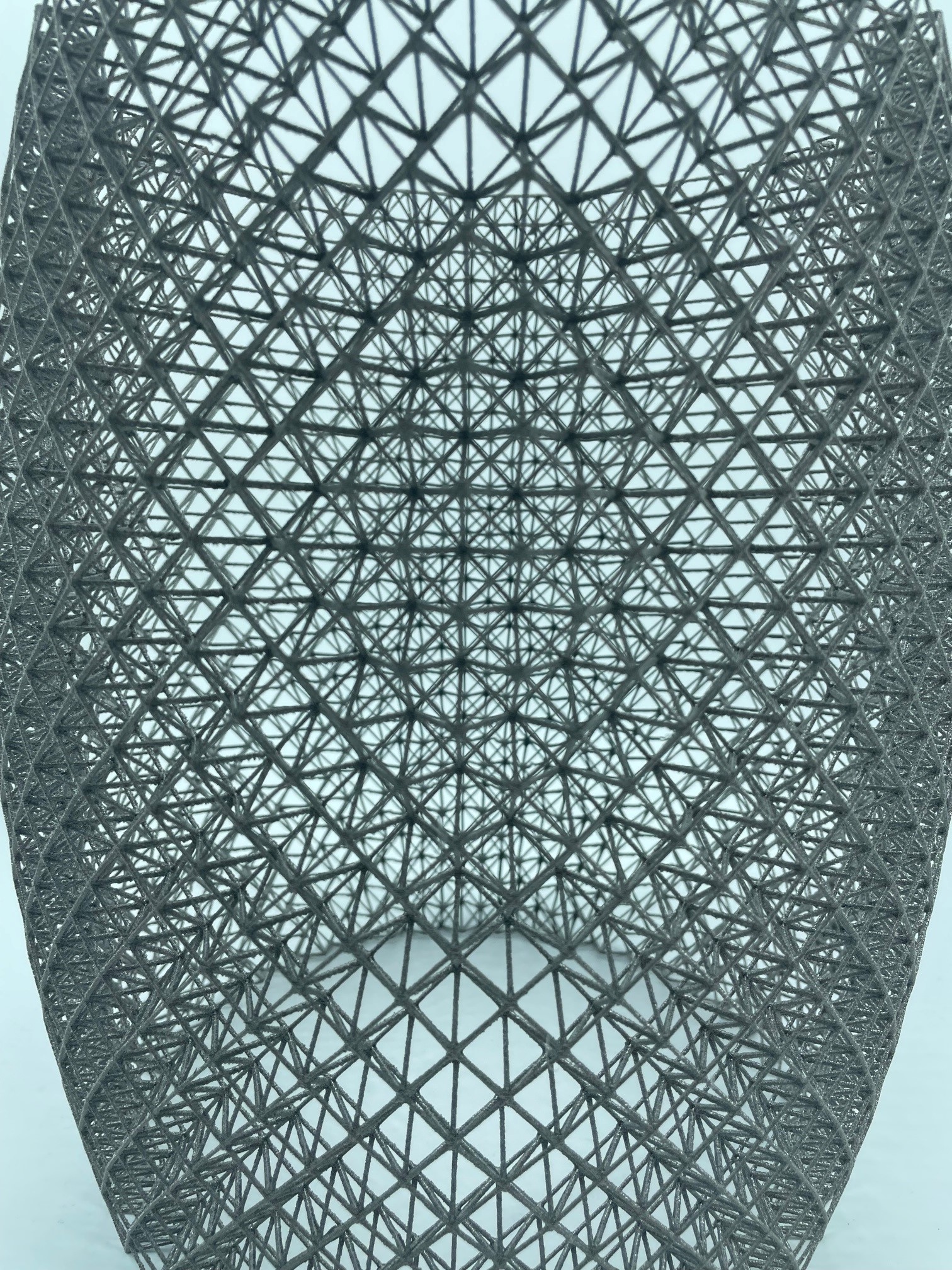

The aerospace and defense industry already uses advanced AM technologies, but faces technological limitations when using exotic materials. Calibur3, equipped with the NeuBeam process, promises a significant advancement in eBeam powder bed fusion (PBF) technology and offers solutions to previous limitations. The stability and versatility of NeuBeam enables the processing of a wide range of industrial materials for production applications beyond the capabilities of existing AM processes.

Peter Hansford, CRO at Wayland comments, “Metal AM, in general, has come a long way and has made inroads for some production applications. Calibur3 has the potential to take production applications to the next level in a number of ways. At AMADS, our team members will be available to discuss new applications and new materials enabled by the capabilities of NeuBeam. We invite AMADS attendees to learn more about our hot part process, which eliminates residual thermal stresses, simplifies powder removal, and reduces post-processing requirements as well as the open approach that allows us to test and prove new material parameters in a matter of weeks.”

With the introduction of Calibur3 and the NeuBeam process, Wayland Additive is positioning itself at the forefront of innovation in 3D printing. The technology not only enables an expanded range of materials for additive manufacturing, but also addresses critical challenges such as thermal residuals and powder removal. The AMADS event will provide a unique opportunity to explore the pioneering capabilities of Calibur3 and discuss the potential of NeuBeam technology for the aerospace industry.

Hansford continues, “Since commercialising our technology two years ago, Wayland is now shipping machines all over the world across a variety of industry sectors, including aerospace, to exploit the potential of our NeuBeam AM process.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.