For a long time, printing with metal filaments was considered one of the biggest hurdles for 3D printing in the home sector. While plastic filaments are relatively easy to process thanks to their comparatively low melting temperatures, the liquefaction of metals requires significantly higher temperatures. The “Glow Plug Turned Metal-Capable 3D Printer Hotend” project by maker Rotoforge could represent a breakthrough here.

The basic idea is as simple as it is clever: a commercially available ceramic glow plug from diesel engines serves as the basis for a modified 3D printing hotend. Thanks to the extremely heat-resistant ceramic material, the glow plug pins can be operated at temperatures of up to 1300 °C. A temperature level that should theoretically enable the processing of common metal wires such as aluminum or brass.

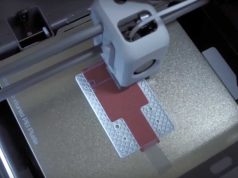

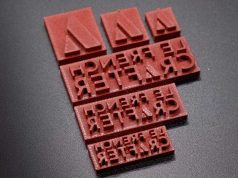

Initial prototypes show promising results. However, some modifications to the glow plug were necessary. For example, the metal components that enable the actual annealing function had to be removed and the ceramic tip had to be carefully drilled to create a material feed-through.

The maker presents his project in a video. He has also published further details on Printables.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.