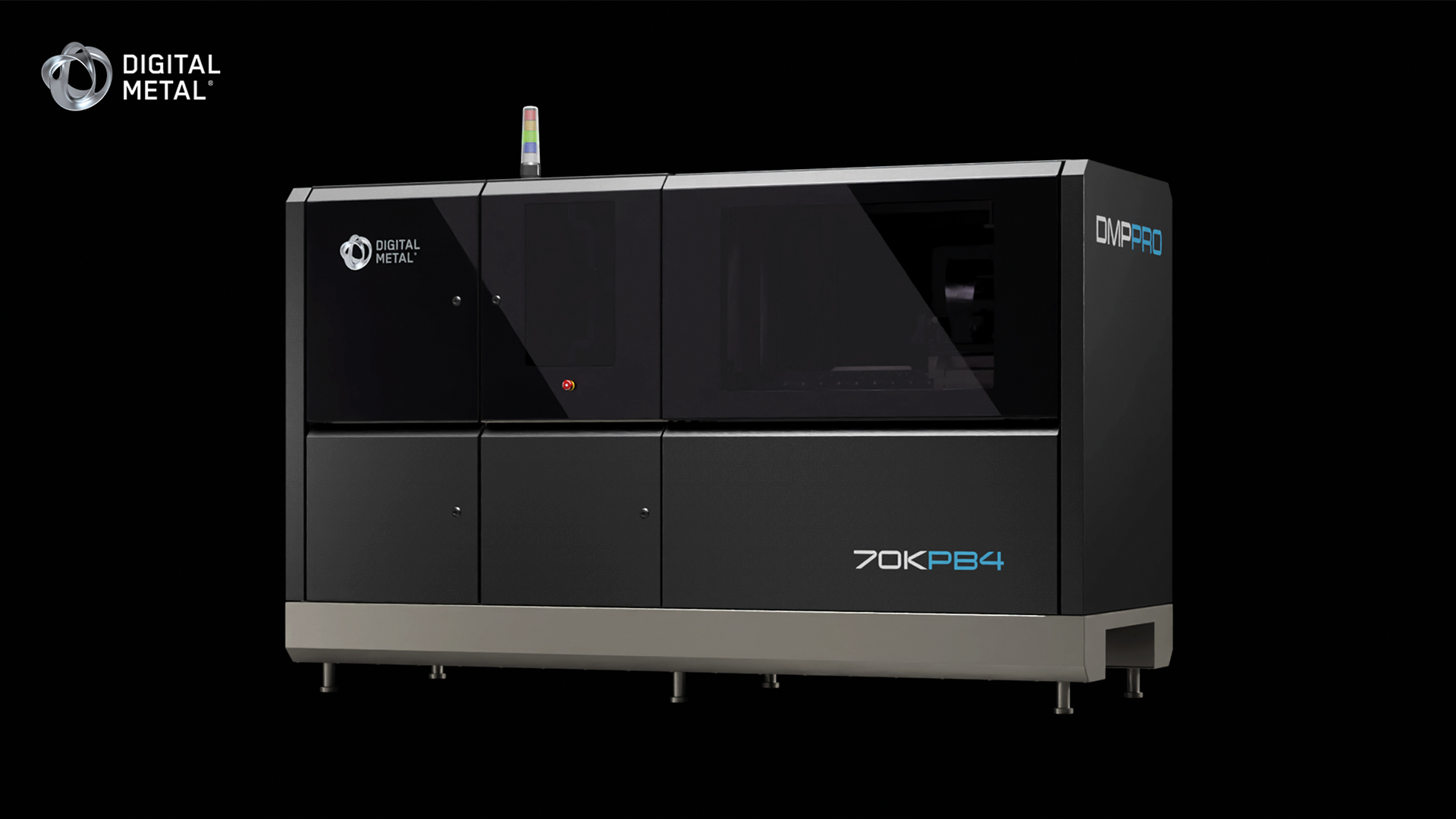

The Binder Jet 3D printer provider Digital Metal announced the launch of its new DMP/PRO binder jet system, developed as a modular component of a complete binder jet solution. The PRO architecture was developed from the ground up to be an industrial binder jet solution for high volume manufacturing with maximum reliability, accuracy and repeatability.

70,400 nozzles precisely deposit material, letting the system produce up to 1,000 cm3 of

parts per hour at 1600 dpi. This high productivity is combined with a robust platform, custom software and a fast material change powder magazine that minimizes downtimes. The DMP/PRO has been engineered for the precision production of metal binder jet components for industry, luxury goods, medical manufacturing and consumer products.

Digital Metal CEO Christian Lönne states,

As a team, we have previously gone from a single machine to a production machine, and now we’ve launched a true production platform. We’re moving away from the rest of the binder jet market towards tighter tolerances, higher volumes and higher precision. We’re heading towards a higher level of maturity. We do not just offer a machine in isolation. We have a true platform optimized to work in concert with debinding, sintering and post-processing equipment. This platform is modular, extensible and a stepping stone for Industrialization.

Azoth 3D General Manager Cody Cochran,

Digital Metal´s new machine speed, while keeping quality and reliability, is compelling. The PRO Series reduces the capital needed to scale and also reduces part costs through higher machine throughput. We want to run it round the clock, 7 days a week,

making thousands of parts daily. Azoth 3D wants to be the largest and best independent binder jet manufacturing company and this is the system we need to get us there.

The DMP/PRO comes equipped with linear motors, air bearings and a diabase stone

base are the foundation of stability process control. Robustly designed for now the

system is also modular, adaptable and future-proof. The current DMP/PRO systems can

be extended in future through inertization and automation modules. It is also completely

customizable, with remote monitoring, KPI monitoring and traceability.

Built on Siemens MindSphere cloud IoT OS the software system ensures that future IoT integration and connections will be reliable and secure. The system is intuitive and easy to use and optimized for production environments. New support structure minimization increases productivity and reduces part cost. Higher powder utilization means that now 100% of excess powder can be recycled. This environmental gain also reduces part costs.

Specifications

- Memjet page-wide print system

- 70,400 ink nozzles

- Machine footprint 2700 x 1000 x1700 mm (L x W x H)

- Build volume 250 × 217 × 70 mm

- Weight 2000 kg

- Typical productivity 500 – 1,000 cm3/h

- Changeover time between prints 15–25 min

(c) Picture & link: Digital Metal

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.