The Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM plans to build a centre for Selective Electron Beam Melting (SEBM) in Dresden, Germany, within the next two years.

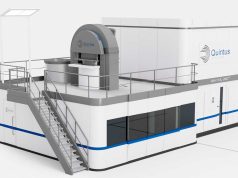

With the order of a Q20plus 3D printer from Swedish manufacturer Arcam, IFAM has just added the second machine for additive manufacturing metal parts to their technology centre. Further systems will follow within the next couple of years.

The Q20plus features the largest build volume of currently available SEBM systems, being able to print parts with a maximum diameter of 350 mm and hight of 380 mm. It uses a high power electron beam to melt metal powder and build stress relieved components layer-by-layer in vacuum. Metals most commonly used are titanium, nickel, steel and other metal alloys.

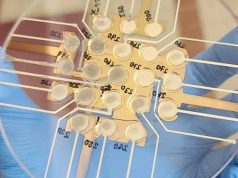

The Fraunhofer IFAM offers their industry partners as well as research facilities services from powder to components, including feasibility studies, the assessment of powders for additive manufacturing as well as the qualification of new materials for SEBM processes. Additionally, the institute develops components as well as manufactures them through SEBM, including post-processing.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.