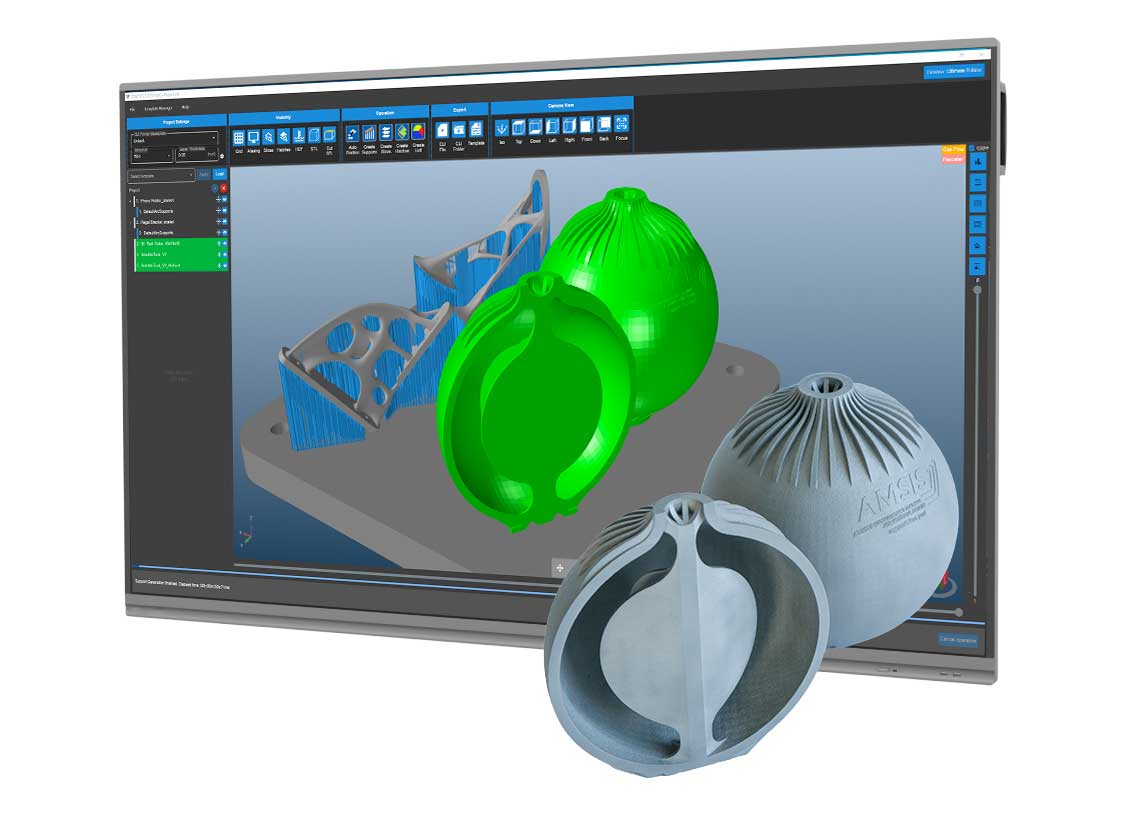

The German company AMSIS presented the fourth generation of its Genesis build job preparation and simulation software at Formnext. According to AMSIS, Genesis 4 enables a significant reduction in support structures when 3D printing metals by simulating laser exposure.

With the help of a fast thermal simulation within a few seconds or minutes, overheated areas of a component can be identified. Based on this, the energy input from the laser is reduced selectively. Together with an optimized hatching for the exposure paths, support structures can be reduced by 10 to 30 percent, according to AMSIS.

Genesis 4 automatically calculates overheated zones and adjusts the process parameters locally without the user having to set this manually. In addition to classic job preparation, the software also offers innovative 3DF hatching patterns that adapt even better to the component contours.

According to Prof. Dr. Vasily Ploshikhin from AMSIS, Genesis 4 enables existing 3D printers to produce components with minimal or no support structures. This reduces material consumption, construction time and post-processing. Thanks to its modular structure, the software can also be easily integrated into existing printer software.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.