Scientists at Lawrence Livermore National Laboratory and Meta (parent company of Facebook, Instagram and WhatsApp) have collaborated to develop a novel 3D printing material. It can mimic the properties of biological tissue, allowing for more realistic wearables.

According to an article in the journal Matter, the researchers can create gradual transitions in stiffness by varying the intensity of light during 3D printing. This mimics natural tissue transitions, such as between bone and muscle.

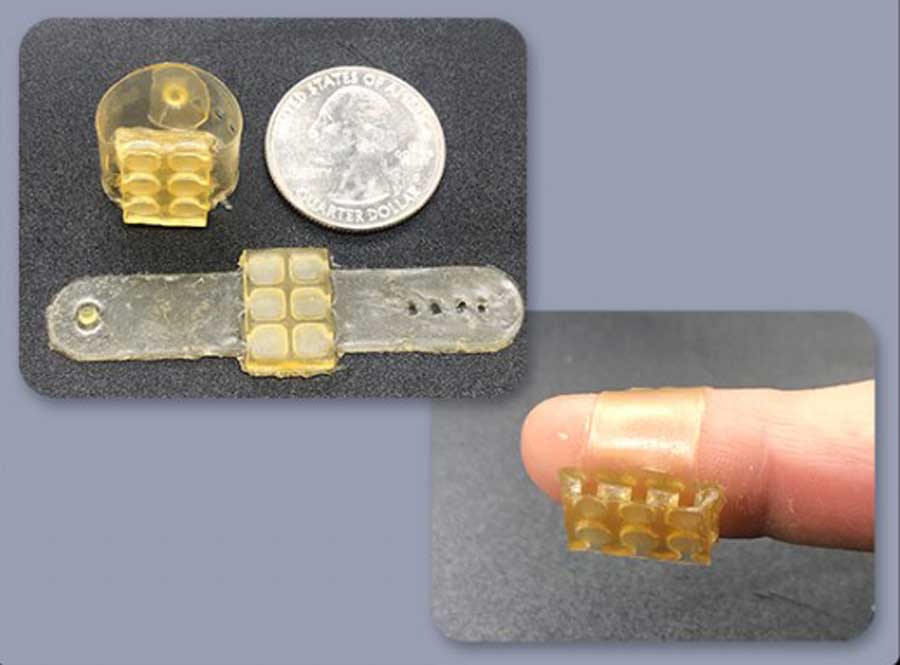

Until now, combining rigid and soft materials for electronics has been a challenge. Now, scientists can manufacture them seamlessly in a 3D printing process. As a demonstration, they printed a wearable Braille display for the finger.

Targeted inflation creates tactile letters. To do this, the material had to be capable of varying local shape, which the new approach achieved. According to the developers, the material is stable over the long term and could be of interest for wearables, soft robotics or shock-absorbing applications.

The organic transitions in stiffness thus enable new possibilities for 3D printing. According to the LLNL researchers involved, the development is a breakthrough for variable plastics that remain stable over time.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.