3D printer manufacturer Markforged has introduced two new print modes for its Metal X system for the metal alloy 17-4PH stainless steel. With “Fine Features”, smaller structures and finer details can be printed. “Turbo” mode allows for much faster print speeds.

According to Markforged, 17-4PH stainless steel has been one of the most popular metal materials for the Metal X system. With the new version 2, the material has been further improved. Now, higher detail and speed modes are added.

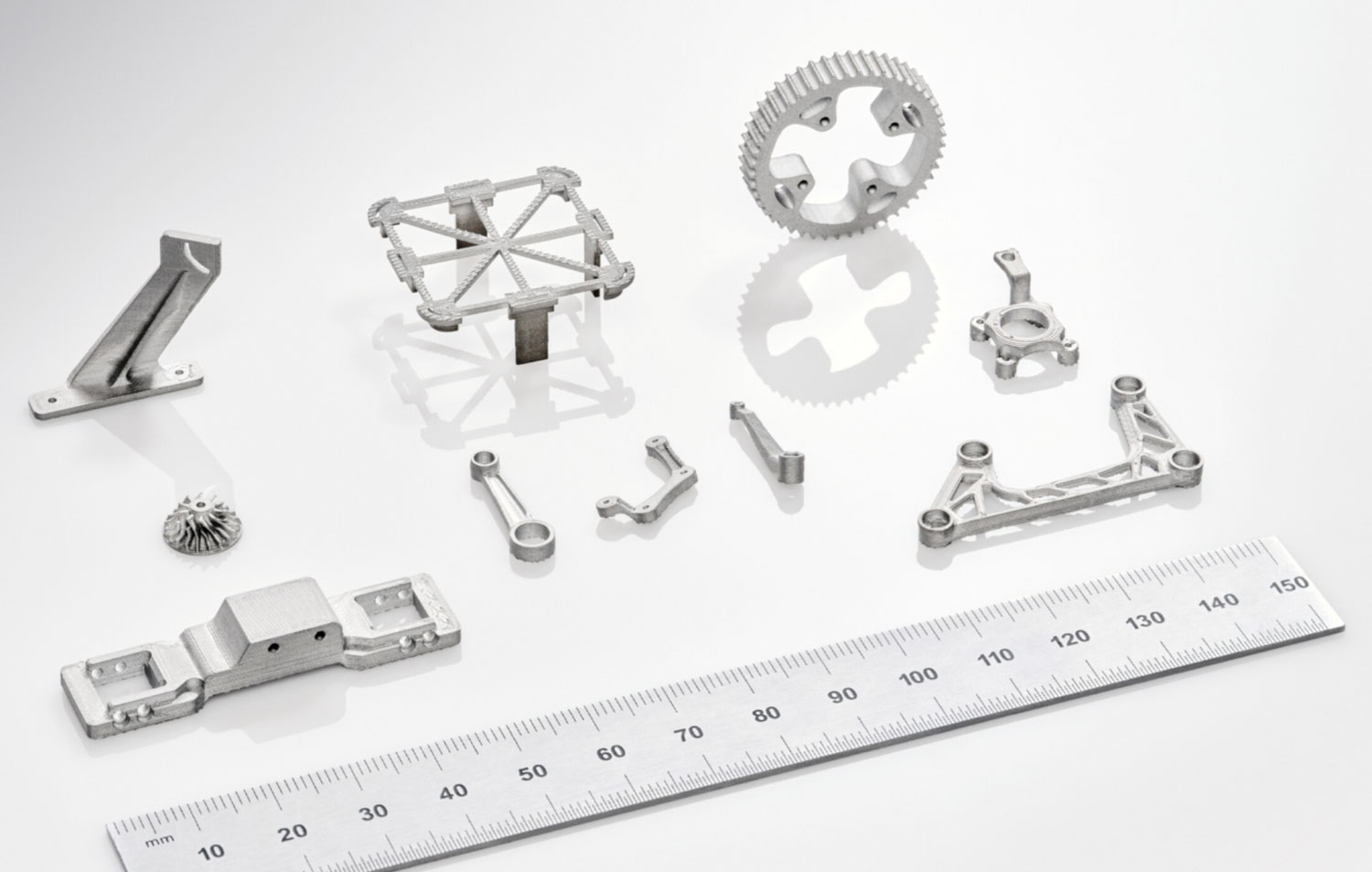

The Fine Features mode prints with only 0.1 mm layer thickness, enabling smoother surfaces and smaller structures. Previously printable parts with small features can be qualitatively improved in Fine mode. In addition, new, filigree designs become possible.

Turbo mode, on the other hand, works with greater layer thicknesses and thus increases print speed by up to 35 percent. According to the manufacturer, hardly any compromises have to be made in terms of part quality. The throughput times of the 3D printers can thus be significantly increased.

With these software-based improvements, Markforged aims to make additive manufacturing of metal components more efficient and flexible. The advantages for fast production and short time-to-market are thus to be expanded.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.