NASA’s Marshall Space Flight Center is the First Customer for Commercial Sale of Feedstock for Additive High-Strength Aluminum

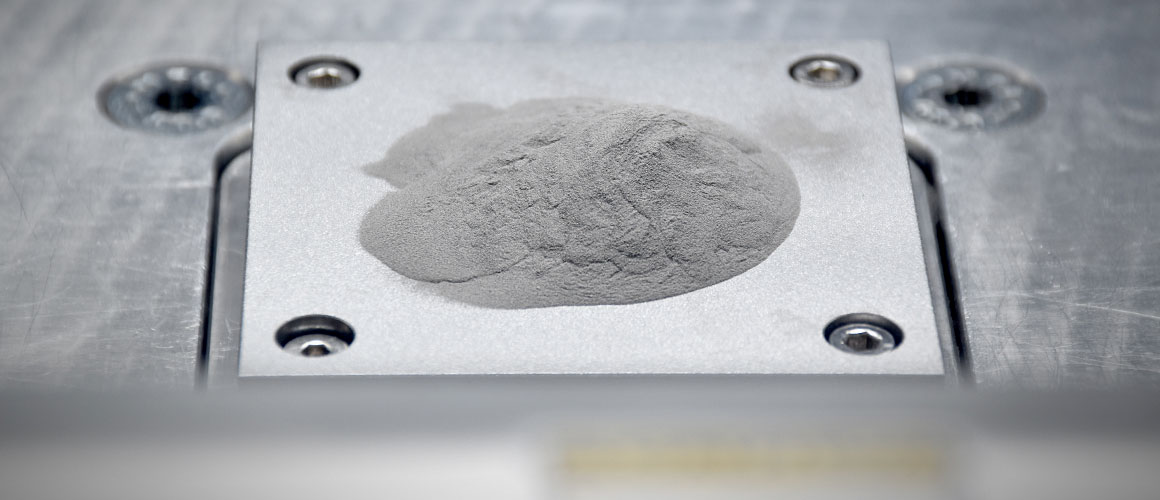

HRL Additive, a new commercial effort by HRL Laboratories, LLC, has secured the first commercial sale of its groundbreaking 7A77 high-strength aluminum 3D-printing powder to NASA’s Marshall Space Flight Center (MSFC). The production plant is dedicated to producing the printable aluminum powder, designated as 7A77, the first additive feedstock registered by the Aluminum Association (AA). Potential customers of high-strength Al 7A77 can now contact Additive[at]HRL.com for a quote or visit HRLadditive.com for more information.

“Our goal is to provide the highest quality powder to HRL’s LLC members in the aerospace and automotive industries, as well as other commercial customers,” said Zak Eckel for HRL Additive.

Besides enabling never-before-printable parts in high-strength aluminum, the feedstock powder can be used with standard off-the-shelf additive manufacturing (3D printing) equipment without any modifications.

“Certainly, the 7A77 feedstock powder could unlock the production of large-scale components produced via fusion-based additive manufacturing,” said Omar Rodriguez of NASA’s Marshall Space Flight Center. “Printed test articles will be subjected to a comprehensive characterization regime expanding several length-scales. The end-goal of this research effort is to expand MSFC’s range of fusion-based additive feedstock materials. If successful in our research endeavor, the feedstock powder could be part of the aerospace-related assets produced at the planed large-scale, advanced manufacturing facility.”

HRL Laboratories engineers announced this historic additive manufacturing breakthrough in their 2017 Nature article 3D printing of high-strength aluminum alloys. Using aluminum feedstock powder functionalized by their exclusive process, the researchers were able to 3D print high-strength aluminum for the first time ever. The achievement has led to a revolution in metallurgy that HRL Laboratories has responded to by producing industrial levels of feedstock in-house.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.