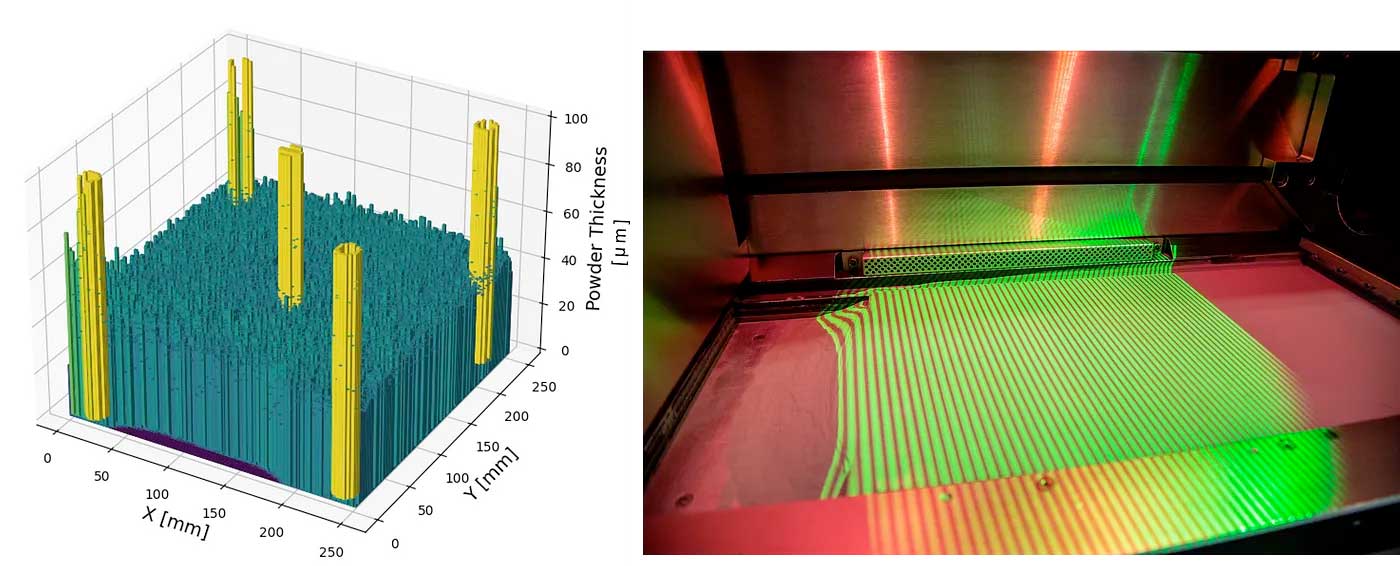

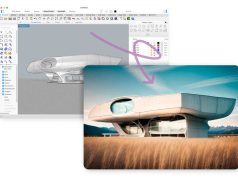

Phase3D, a Chicago-based company commercializing in-situ monitoring for additive manufacturing, is pleased to announce the launch of True Layer Thickness. This toolkit measures the amount of metal powder in microns distributed across the build area and certifies uniform distribution for each layer in every build.

The introduction of True Layer Thickness comes at a time when regulated industries such as aerospace, medical and energy are looking for ways to further develop AM for critical applications. By utilizing monitoring solutions directly in the production process, they aim to produce parts that are certified from the start. Phase3D worked closely with a leading aerospace company to develop the toolkit, which addresses a key need for high quality part production.

Dr. Niall O’Dowd, CEO and Founder of Phase3D, expressed enthusiasm about the release, stating, “We are pleased to introduce True Layer Thickness. This new toolkit underscores our commitment to advancing AM for the benefit of widespread adoption of the technology for critical use applications.”

The key elements of True Layer Thickness include objective data capture using patented fringe monitoring technology, precision and consistency in the inspection of the deposited metal powder and seamless integration with Phase3D’s existing fringe monitoring system. This enables seamless support from product development to production.

The True Layer Thickness Toolkit is a significant step forward for the AM industry to realize certified productions. With fringe monitoring and True Layer Thickness, objective measurement data can now be captured to inspect each print in real time. The toolkit will be available to all Phase3D customers and can be viewed at AMUG 2024 in Chicago, IL, at booth 101 in Salon D.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.