German-based Primetall offers a comprehensive range of solutions tailor-made from high-quality stainless steel. They work closely with their customers to provide the absolute best service. By bringing consulting, design, and production under the same roof, they offer shorter timelines, better service, and more know-how. Their products have a reputation for precision, quality, and durability.

The team was drawn to the Markforged platform to manufacture parts printed from and reinforced with continuous fibers. Plus, they found the hardware and software easy to learn, requiring only a minimum level of training before they were up and running. Cloud-based software like Eiger gave Primetall even more options.

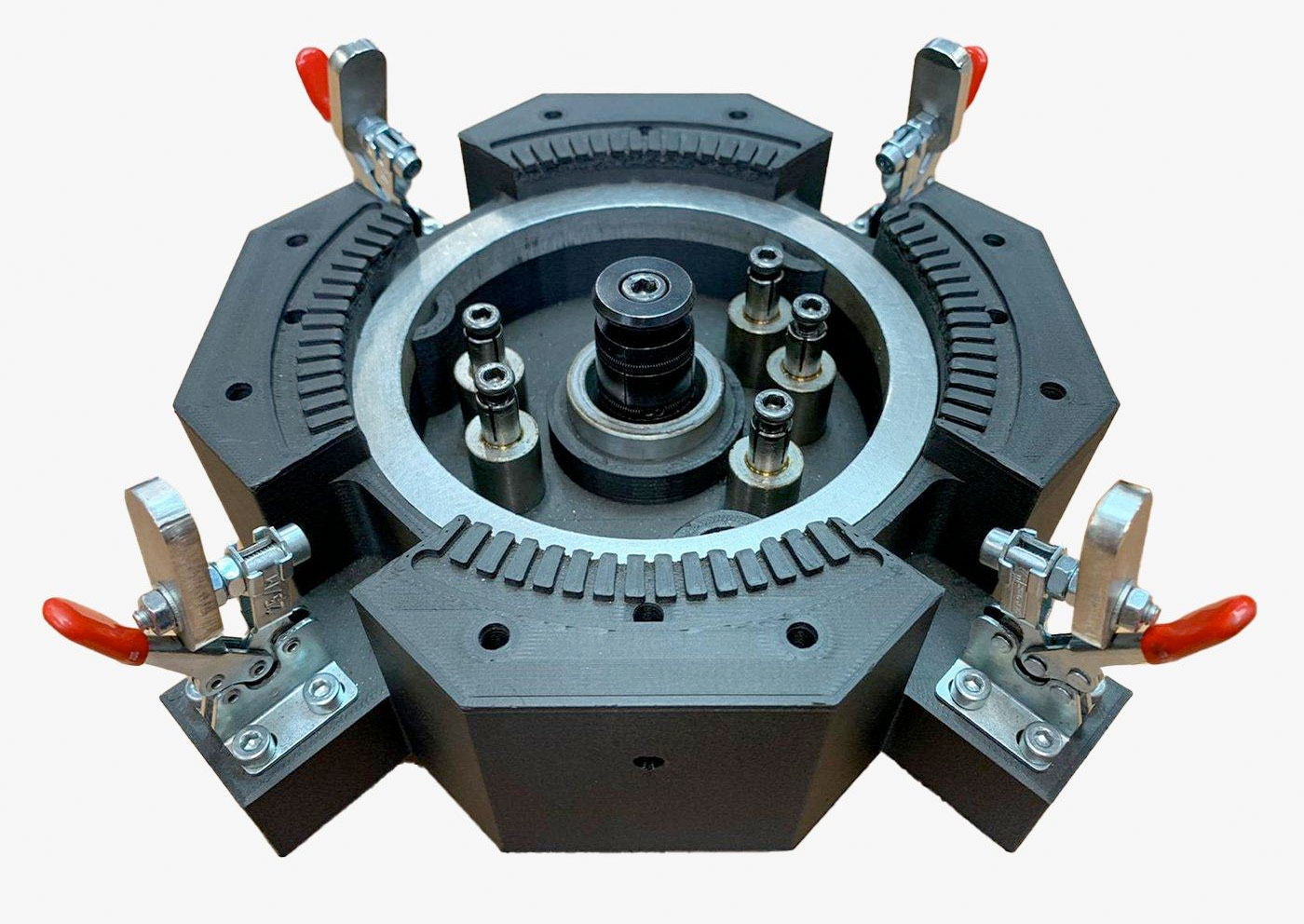

These welding machine fixtures have the durability and dimensional stability to withstand the stresses of holding heavy steel parts while rotating at high speeds. Moreover, the reduced weight compared to the steel original improves the cycle time of the laser welding process. With the design flexibility afforded by Markforged 3D printers, Primetall’s engineers were able to manufacture the prime to accept a zero-point clamping system, further contributing to faster processing times. After a resounding success with the clamping fixtures, the engineers broadened the scope of composite printing to gas ducts, which are critical for clean welding.

For more information about Primetall, please visit primetall.de.

Find out more about Markforged at markforged.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.