Researchers have shown for the first time that 3D-printed polymer-based micro-optics can withstand the heat and power levels in a laser. This advance enables low-cost, compact and stable laser sources that could be useful for a variety of applications, including lidar systems for autonomous vehicles.

“We significantly reduced the size of a laser by using 3D printing to fabricate high-quality micro-optics directly on glass fibers used inside of lasers,” said research team leader Simon Angstenberger from the 4th Physics Institute at the University of Stuttgart in Germany. “This is the first implementation of such 3D-printed optics in a real-world laser, highlighting their high damage threshold and stability.”

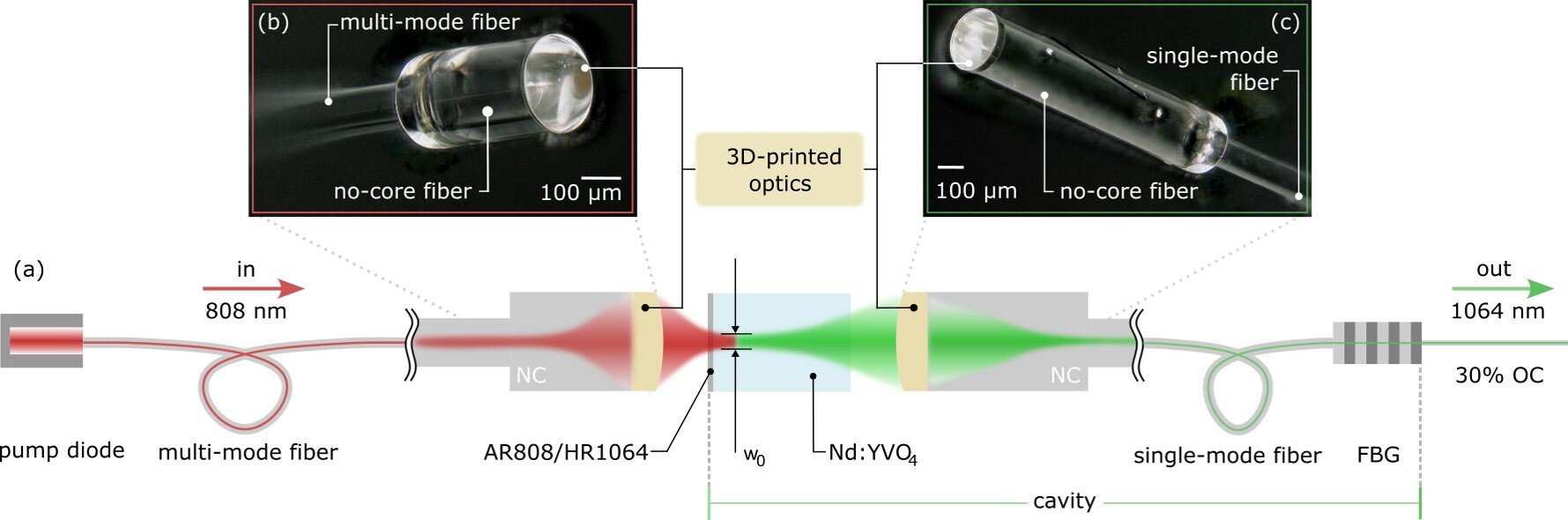

In the journal “Optics Letters”, the researchers describe how they 3D-printed microscale optics directly on optical fibers to compactly combine fibers and laser crystals in a single laser oscillator. The resulting hybrid laser showed stable operation at output powers of over 20 mW at 1063.4 nm and reached a maximum output power of 37 mW.

The new laser combines the compactness, robustness and cost-effectiveness of fiber-based lasers with the advantages of crystal-based solid-state lasers, which can exhibit a wide range of properties such as different powers and colors.

“Until now, 3D-printed optics have primarily been used for low-power applications such as endoscopy,” said Angstenberger. “The ability to use them with high-power applications could be useful for lithography and laser marking, for example. We showed that these 3D micro-optics printed onto fibers can be used to focus large amounts of light down to a single point, which could be useful for medical applications such as precisely destroying cancerous tissue.”

The 4th Physics Institute at the University of Stuttgart has a long history of developing 3D printed micro-optics, particularly the ability to print them directly onto fibers. They use a 3D printing approach known as two-photon polymerization, in which an infrared laser is focused into a UV-sensitive photoresistor.

For the study, the researchers used a Nanoscribe 3D printer to fabricate lenses with a diameter of 0.25 mm and a height of 80 microns at the end of a fiber with the same diameter. This required extremely precise alignment of the print to the fiber and high accuracy of the printing process itself.

“Because these 3D-printed elements are made of polymers, it was unclear whether they could withstand the significant amount of heat load and optical power that occurs inside a laser cavity,” said Angstenberger. “We found that they are surprisingly stable, and we were not able to observe any kind of damage on the lenses even after several hours of running the laser.”

Once the printing was complete, the researchers assembled the laser and the laser cave. Instead of using a crystal in a bulky and expensive laser mirror cavity, they used fibers to form part of the cavity, creating a hybrid fiber-crystal laser. The lenses printed at the end of the fibers focus and collect – or couple – the light in and out of the laser crystal.

The researchers are now planning to optimize the efficiency of the printed optics. Larger fibres with optimized freeform and aspherical lens designs or a combination of lenses printed directly onto the fibre could help improve output power. They would also like to demonstrate different crystals in the laser that could enable output customization for specific applications.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.