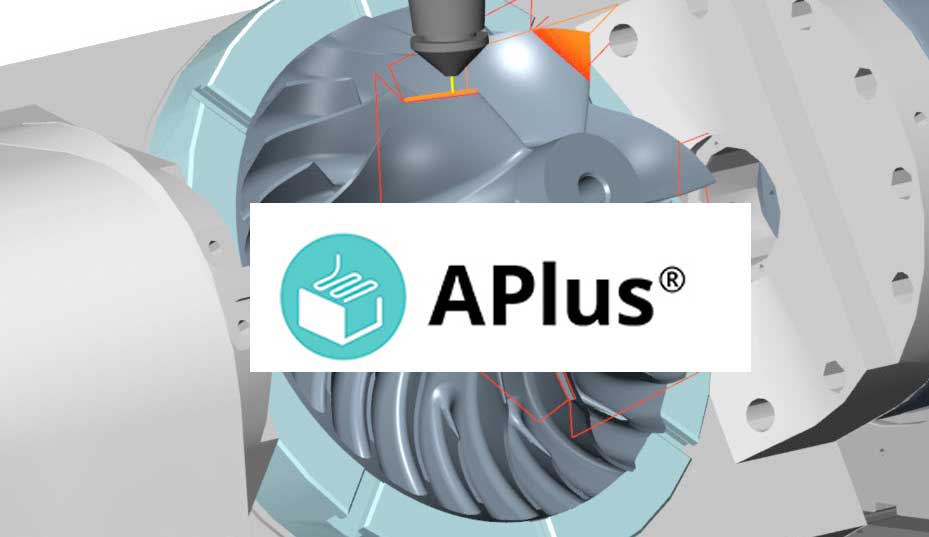

Software developer Mastercam has introduced APlus, a new add-on for additive manufacturing. Using the same interface familiar to Mastercam users, APlus users can program, deposit and simulate their 3D printing applications just as they would with traditional toolpaths in Mastercam.

Another highlight is the use of Direct Energy Deposition (DED), a technology developed specifically for the needs of additive manufacturing. APlus includes toolpaths that can handle any geometry in additive manufacturing. It also includes special features that make the process more efficient and less error-prone.

Kenneth Fortier, Technical Product Manager, Mastercam says “APlus brings Additive Manufacturing to the Mastercam user in a form that is consistent with the workflow used for over 40 years. Direct Energy Deposition is making its way into many machine shops and being able to program hybrid machines or dedicated additive machines using Mastercam makes the transition seamless. With the hybrid process of alternating adding material and milling allows parts with internally machined features to be created that would have been impossible without additive.”

An example of the practical application of APlus is the repair of turbine blades. If the tips of the blades are worn, the user can machine them with Mastercam and remove the worn areas. Then APlus can be used to print or apply material to the machined areas. Finally, the printed areas are machined to the desired specifications. This process can save significant costs compared to buying or making a new replacement part.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.