NASA is working to build a research base on the moon to send the first astronauts to Mars. Brandon Aguiar, a student from Florida, is further developing a 3D printing technique to create permanent structures from lunar dust.

“It’s very expensive to ship supplies to space. One pound of material can cost thousands of dollars,” says Aguiar, a life-long fan of space exploration. “Just imagine what it would cost taxpayers to ship entire houses to the moon. Instead, we can use the material that is already there to build infrastructure.”

The student is focusing on how his 3D-printed objects can withstand the hazards of the moon, including radiation, asteroids and temperature fluctuations. To do so, he works in FIU’s Plasma Forming Lab under the guidance of technology experts* such as Ambreen Nisar, an assistant professor who researches ceramic materials for space exploration and hypersonic vehicles.

“On Earth, temperatures are very different depending on where you go. The weather in Miami is super hot, but somewhere in the northwest, it’s still freezing. The same happens when you are on the moon,” Ambreen Nisar said. “Any material that is used needs to withstand extreme thermal shock.”

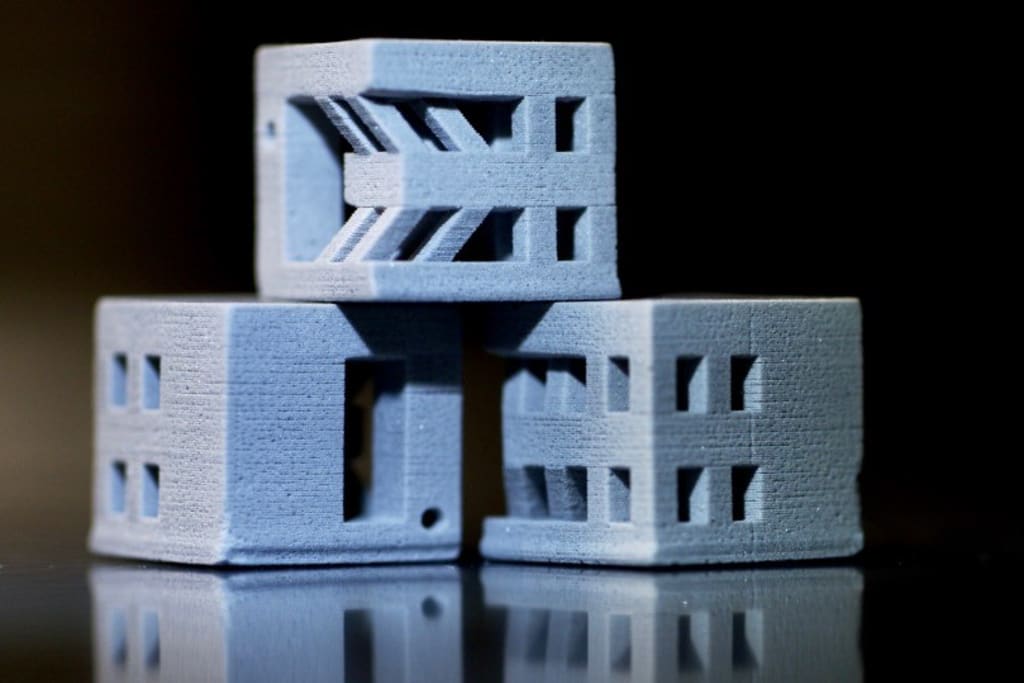

Aguiar mixes lunar dust with a resin that acts like a glue to bind the small rocks together. He then 3D prints the material and runs it through an oven to get the desired shape and burn away the resin. The key is getting the parameters of the 3D printing and treatment process right.

It’s like cooking, Aguiar says; the ingredients and parameters have to be just right. That’s what he learned from Professor Arvind Agarwal, head of the plasma imaging lab.

“When I’m teaching my new students, I always use the example of cooking to explain materials engineering,” Agarwal says. “You can make a chicken into either grilled chicken or fried chicken. The taste is completely different, but the starting material is the same. The same goes for lunar dust used in Brandon’s research. By modifying how he ‘cooks’ the dust, he can completely change how his structures perform.”

Aguiar will continue his research as a doctoral student at FIU under a presidential grant. His 3D printing process and parameters are patent pending and were recently published in a peer-reviewed journal. Aguiar’s research is a continuation of a final project by FIU doctoral student Kazue Orikasa, who is now researching how plastics could be used to protect technologies in space.

Find out more about the FIU at fiu.edu.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.