The flexible and impact-resistant 3D printing material TPU (thermoplastic polyurethane) is becoming increasingly popular due to its outstanding material properties. Printing with TPU was considered difficult and error-prone. However, further developments have made it easier. In a video, YouTuber Angus from Maker’s Muse explains the improvements.

The main problem with TPU printing is the flexibility of the material. The elastic filament strands tend to jam or twist in the extruder. However, modern direct-drive extruders with steep filament feed prevent this quite reliably. Current TPU filaments have also been specially optimized for 3D printing and deform less easily.

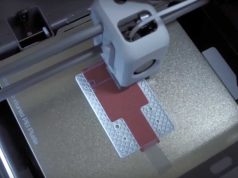

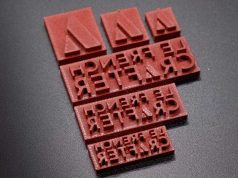

According to Maker’s Muse, it is now even possible to print support structures from TPU that can be removed after completion. When removing them, it helps to pull on one corner with as much force as possible, similar to Velcro fasteners.

To reduce stringing, the YouTuber recommends activating retractions, drying the material before printing and keeping the printing movements within the contours. Maker’s Muse has also developed its own printing profile for particularly light yet stable TPU parts.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.