UpNano, an Austrian company, has unveiled a new software upgrade for its high-resolution NanoOne 3D printing platform. This upgrade promises to further increase print speed while improving the quality of the printed product through intelligent “stitching.” In addition, the upgrade offers the ability to combine different print jobs into a single job, resulting in further cost savings.

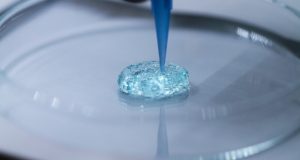

2-photon polymerization (2PP) is a key feature of UpNano printers, which are considered the fastest of their kind. This technology has been responsible for past innovations in areas such as electronics, micro-optics and medical research.

With the new upgrade, users can now customize multiple print parameters. This enables even more precise control of the printing process and end product quality. A particular focus was on the problem of seams in 3D-printed products.

“Now, products with exactly defined seams can be printed”, explains Denise Hirner, COO and co-founder of UpNano.

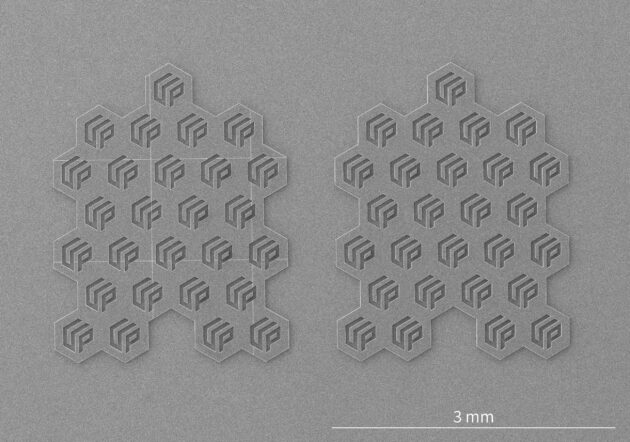

Stitching is a serious quality issue in 3D printed products. They arise from the need to move the lens field of view during printing and to stitch together the printed elements of each field of view (“stitching”).

“The unique features of our latest upgrade help to reduce this”, adds Denise Hirner. “By addressing more parameters individually and dynamically, it is now possible to define the exact positions of stitching lines. Depending on the final structure, this allows for a smart integration of the seams into the design.”

Another notable feature is dynamic resolution adjustment. Users can now change the resolution within a print job, which adjusts the print speed as needed.

“One can print less defined parts quickly and step-by-step increase the resolution of the process as one comes to the finer defined structural elements”, explains Denise Hirner. “In this way very neat printing of complex structures with different requirements for resolution becomes possible and this can save up to 50% time.”

The upgrade also allows different print jobs to be merged, as long as the same material and lens are used. This not only increases efficiency, but also ensures better utilization of the print substrate.

Denise Hirner adds: “Just recently we held our annual customer event – an occasion where we always learn a lot about the evolving requirements of our worldwide customer base. With our latest software upgrade a lot of those needs are met, and we are very excited to further improve the performance of our printers together with our valued NanoOne customer network.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.