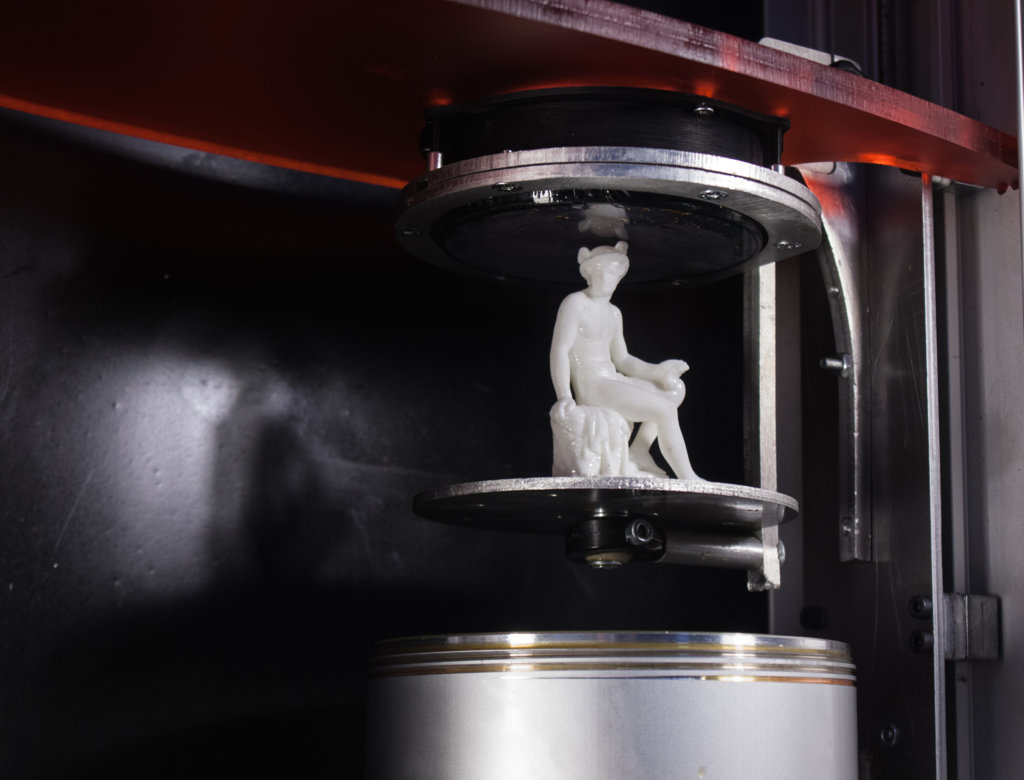

While the World’s Advanced Saving Project (WASP) is pursuing their goal to 3D print affordable and sustainable homes, they have also been working on a 3D printer based on digital light processing (DLP) technology for the past three years.

As a result, they present TOP DLP and will launch the affordable device within the next couple of month. Unlike other 3D printers working with DLP technology – a process where photosensitive resin is cured layer by layer by using light – TOP DLP has its light source placed on top, as the name implies. WASP has worked with a bottom-to-top version first, but was set back by the maintenance it requires. In order to prevent the layers from sticking to the print plate, a silicon layer has to be applied to the bottom of the resin container. This anti-adhesive layer dissolves over time and either the layer or the vat including resin has to be replaced.

Their top-down system solves this issue, as WASP explains:

“This mechanism solves the issue of the piece’s detachment from the projection plane, with up to 100% print success rates. Once the operation is complete, a special, watertight lid closes the vat (which can be replaced even during the printing process), thus reducing cleaning requirements and related issues.”

WASP also added a filter systems to eliminate unpleasant odour and fumes.

Visitors of the Rome Maker Faire, taking place from October 16 to 18, will be able to get a glimpse of WASP’s TOP DLP.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.