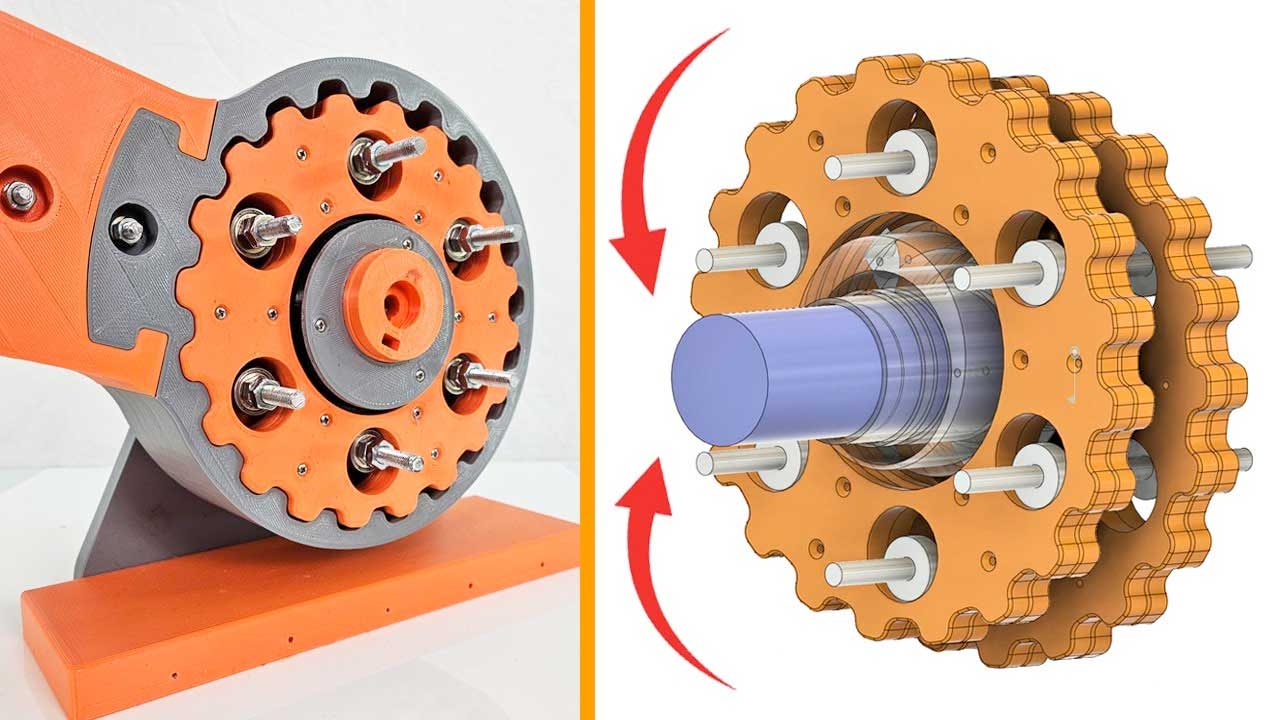

YouTuber and maker James Bruton has presented a self-designed cycloidal drive with an integrated 3D-printed comb wheel in a new video. This is a clever design in which a motor with an integrated gear head is built directly into a 3D-printed hub.

According to Bruton, this design enables a very compact and space-saving construction. The advantage over conventional cycloidal gears lies in the direct integration of the drive motor, which means that fewer bearings and components are required.

Bruton uses a robust and wear-resistant filament to print the large and heavy-duty comb wheel. The comb wheel has 21 teeth and rotates at a ratio of 20:1 to the outer housing. Two cam disks are rotatably mounted on ball bearings and thus generate the characteristic “traveling movement” of the cycloidal gear.

In tests, the design proved to be very resilient and the motor with integrated 99.5:1 gear head delivered sufficient torque. However, there were initially problems with the mounting of the motor, which Bruton was able to solve by adapting the design. Now the gearbox runs smoothly and with low wear, despite the high forces involved.

Thanks to its compact design and the ability to print many components directly, this design is ideal for use in larger robotics projects. James Bruton is already planning its use in future projects. As always, he is making all the associated components freely available on GitHub.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.