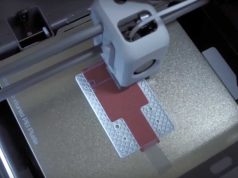

The 3D-printed prototype by YouTuber “Fraens” works on the principle of the vibration-powered conveyor trough. The core piece is a shell on spring-mounted inclined springs. Between the shell and the base plate is an electromagnet, which generates the vibration via a sine wave.

According to the developer, the springs in particular are elementary for the function. In numerous tests and iterations, their stiffness was optimized to produce the small throw of the parts. Matching the magnet force, spring preload and operating voltage is also crucial. Otherwise, the shell will stick to the magnet.

The electromagnet is driven by a special circuit that allows the coil current direction to be switched. This minimizes the sluggish buildup and decay of the magnetic field. At its heart is a microcontroller that generates a sine wave as the drive signal via a DDS (Direct Digital Synthesis) algorithm.

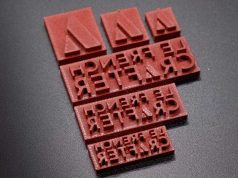

3D printed manufacturing not only enables low-cost prototyping, but also the integration of electronics and mechanics. In a comprehensive article, the engineer explains his development. On the 3D model platform Cult, the maker sells instructions and the associated 3D models for 20 euros.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.