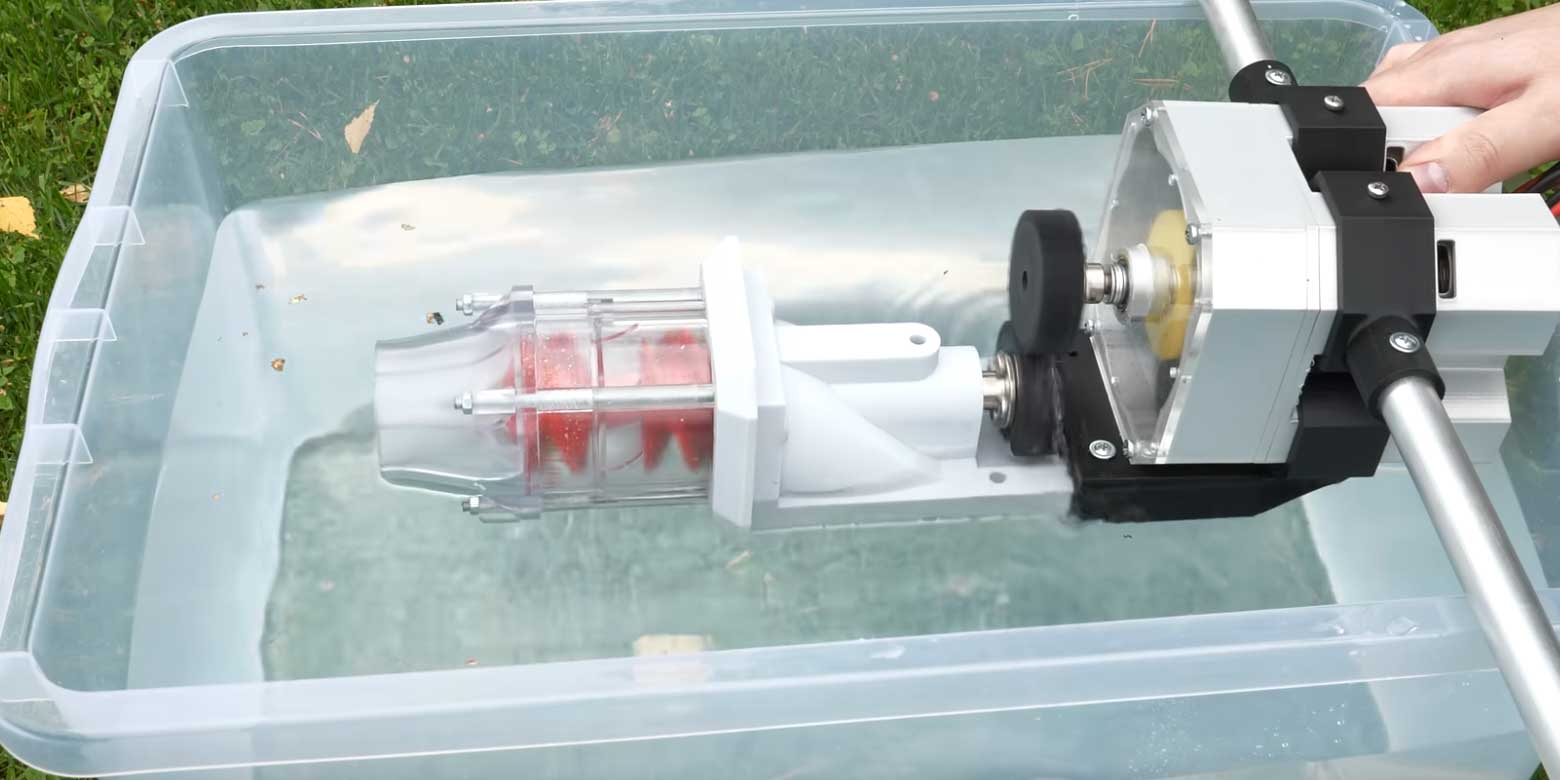

On the YouTube channel “Let’s Print“, a maker has produced a water jet propulsion system for boats completely using 3D printing. The video documents in detail how the individual parts of the jet propulsion system are designed, printed and finally assembled into a functioning propulsion system.

According to the Maker, a waterjet propulsion system consists of four main components: the housing, the turbine, the nozzle, and the control unit. In his project, he designed and 3D printed both a very simple single-stage turbine and a two-stage turbine.

He says a resin 3D printer was used for the fabrication. The turbine was printed from a durable ABS-like resin, and the housing parts were printed from transparent resin. To make the parts more transparent, they were wet sanded and painted after printing.

As the final video shows, the 3D-printed waterjet actuator works flawlessly. In a large pool of water, the model boat equipped with the turbine reaches a remarkable speed.

According to the YouTuber, despite the working technology at its core, the project was simple to implement. The biggest challenge was the accuracy of fit during assembly. This is where the strengths of 3D printing come into play, as parts can be easily adapted and replaced.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.