The YouTuber behind the Let’s Print channel has set himself an ambitious goal: to produce a functioning axial compressor using 3D printing. Such a project is new to him and poses a number of challenges.

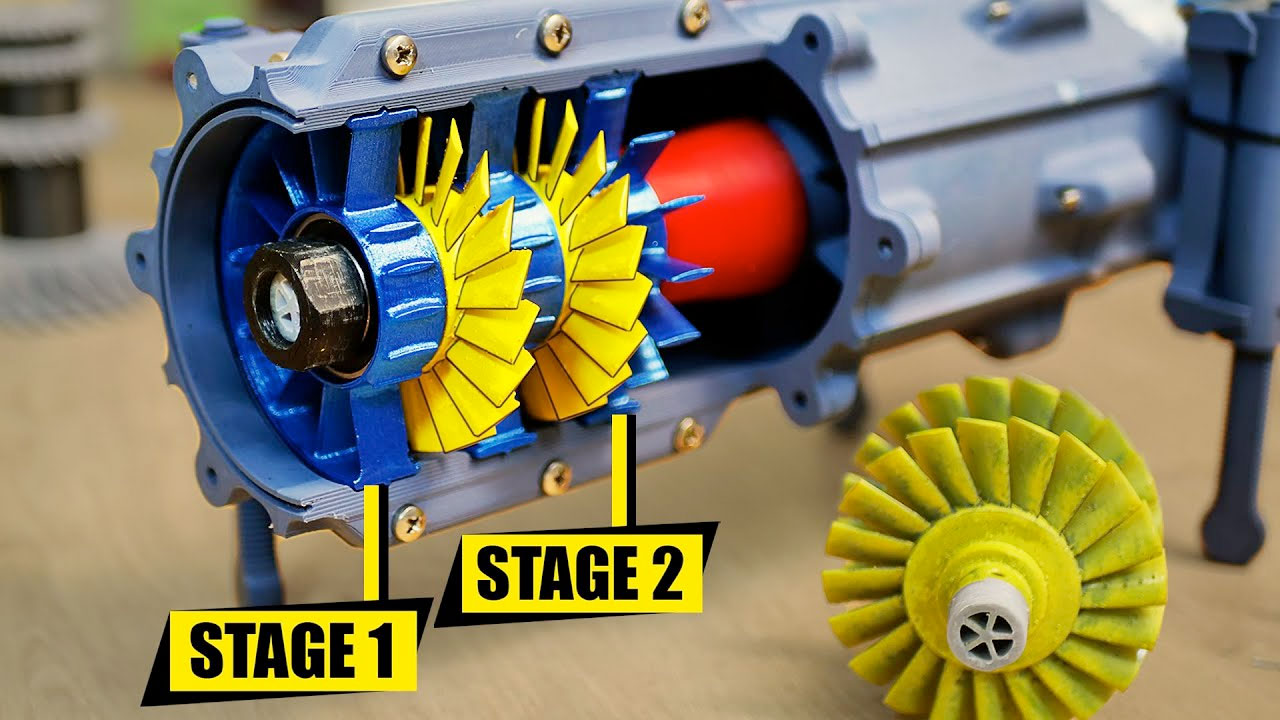

He uses a freely available 3D model from Thingiverse as a basis, which he says he has modified slightly. With the help of two very precise 3D printers and a resin printer, he produces the individual parts he needs and assembles them step by step.

The small rotor blades, which have to be printed very precisely and then “pressed in”, present him with particular difficulties. The coupling between the motor and rotor unit breaks several times during the test run, which the YouTuber gets under control by making design adjustments.

However, the functional tests show that the suction effect of the 3D printer compressor is not sufficient to inflate a balloon or similar. According to the YouTuber, this is due to the inadequate geometry of the guide vanes. By completely redesigning them with significantly more blades, he achieves a slight improvement in performance in a new test.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.