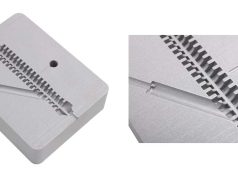

YouTuber Stefan from CNC Kitchen has tackled a problem with multi-material 3D printing: the large amounts of print waste generated. When switching between different filaments, the common nozzle has to be cleaned, which creates so-called “purge pops”.

For a 500 gram multi-color print, over 1 kilo of this waste was produced. Stefan wanted to turn this waste back into usable filament. Tests with a filament extrusion machine from 3Devo showed that the waste first had to be shredded and the material had to be absolutely dry and free of impurities.

Moist “purge poops” produced filament with a very fluctuating diameter, which interfered with printing. Only after drying and using fresh waste was it possible to produce a filament that was easy to process. According to Stefan, the video shows that it is possible in principle to recycle printing waste into usable filament, despite the complex laboratory equipment.

For home users, the costs and effort involved are higher than the benefits. Nevertheless, Stefan sees great potential for closing the material cycle in 3D printing and recycling waste. The proof of concept can also be implemented with cheaper kit solutions.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.