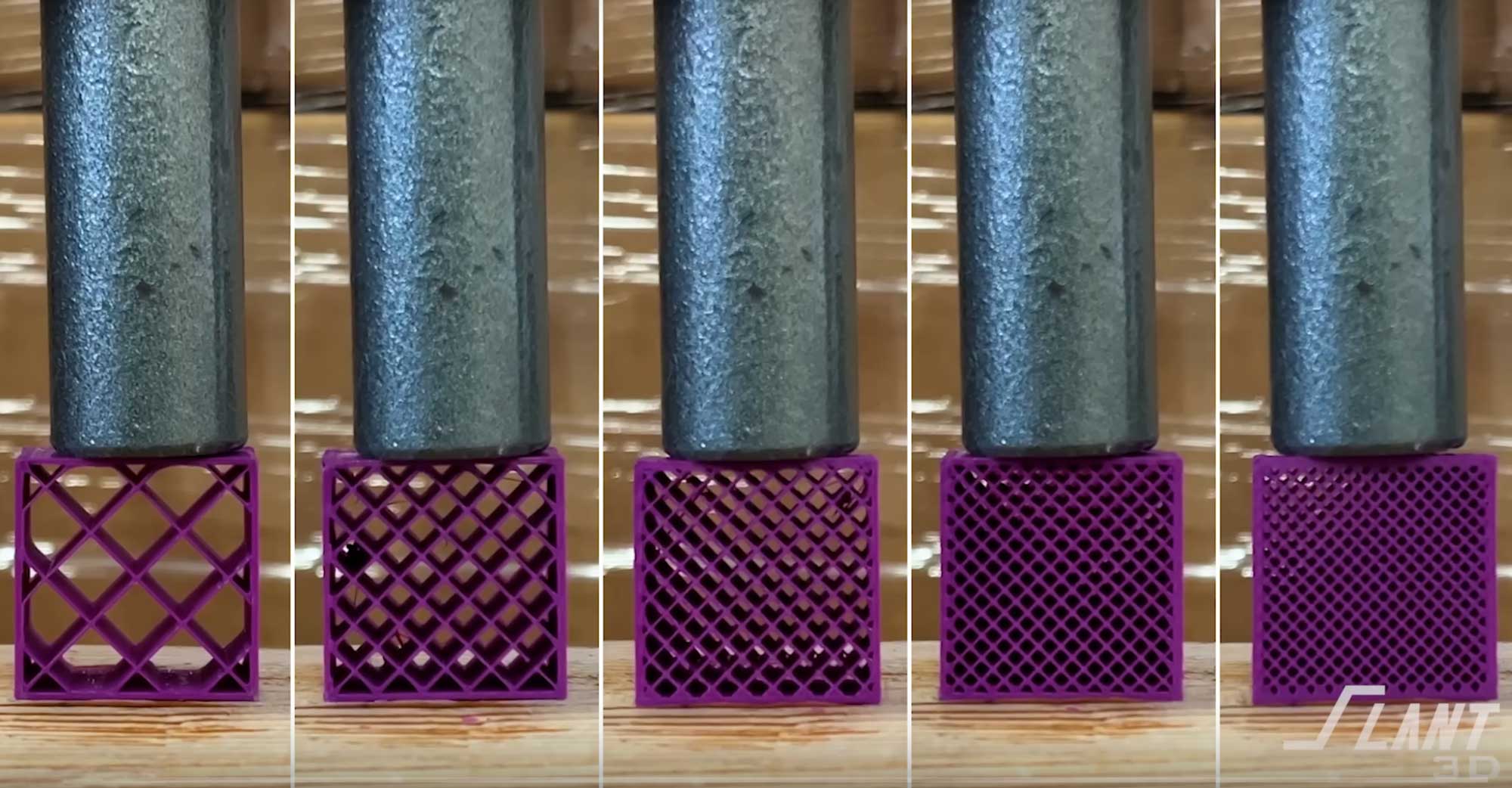

In a new video, the YouTube channel “Slant 3D” has investigated how different infill densities affect the compressive strength of 3D printed objects. Using a compression test setup, the team measured the maximum compressive load that cuboid test prints with infills from 10% to 100% can withstand.

30mm cubes were tested in 10% increments, starting with a weak 10% infill. The material used was a commercially available PLA. A hydraulic press with a force sensor was used to measure the compression force.

As the ascending series of tests showed, the compressive strength nearly doubled for each 10 percent increase in infill density. From about 50% infill, however, the effect decreased, as there was hardly any air left inside.

According to the measurement results, an infill of around 50% is sufficient for many applications. Higher values hardly bring any strength advantages. A compressive force of over 500 kg could be measured before the setup reached its limits.

The video clearly illustrates the influence of the infill density on the mechanical properties. For users, it makes sense not to select a higher value than necessary, as this saves time and material. Which value is optimal in a specific case depends on the component and the load.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.