Youtuber Adam Harig took on the challenge of testing the load-bearing capacity of 3D-printed threads. In a video experiment, he investigated whether such threads are suitable for fastening expensive equipment.

According to Harig, 3D printing still needs a lot of clarification as to how far designs can be loaded before they break. Screw-in threads are often reinforced with extra metal. But how resilient are purely 3D-printed threads?

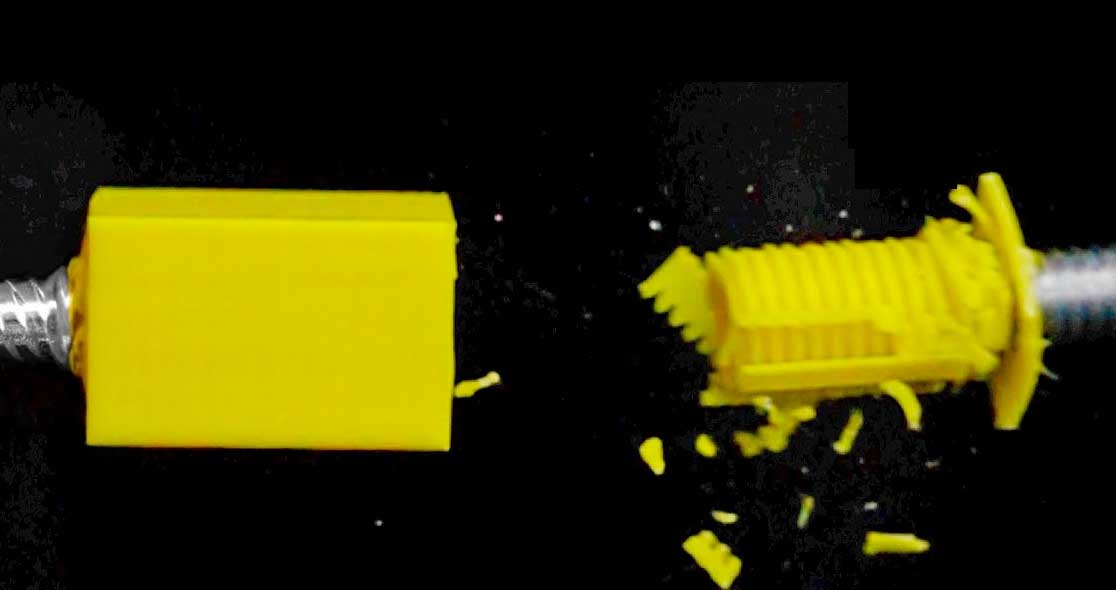

To find out, Harig produced simple cubes with internal threads made from PLA plastic. In his video, he pulled these apart using a scale to determine the maximum tensile strength. Versions with different internal structures were tested.

According to Harig, the version with 100 percent infill was the most durable. At the maximum tensile strength of over 150 kilograms, it was not the thread that broke, but the bottom layers of the cube. The result gave the Youtuber enough confidence to hang a camera system from one of the 3D printed parts.

Harig comes to the conclusion that 3D-printed threads can certainly be useful. However, in addition to tension, other loads such as torsion should also be investigated. Nevertheless, the tinkerer believes that the use of 3D printed threads is justifiable for many applications.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.