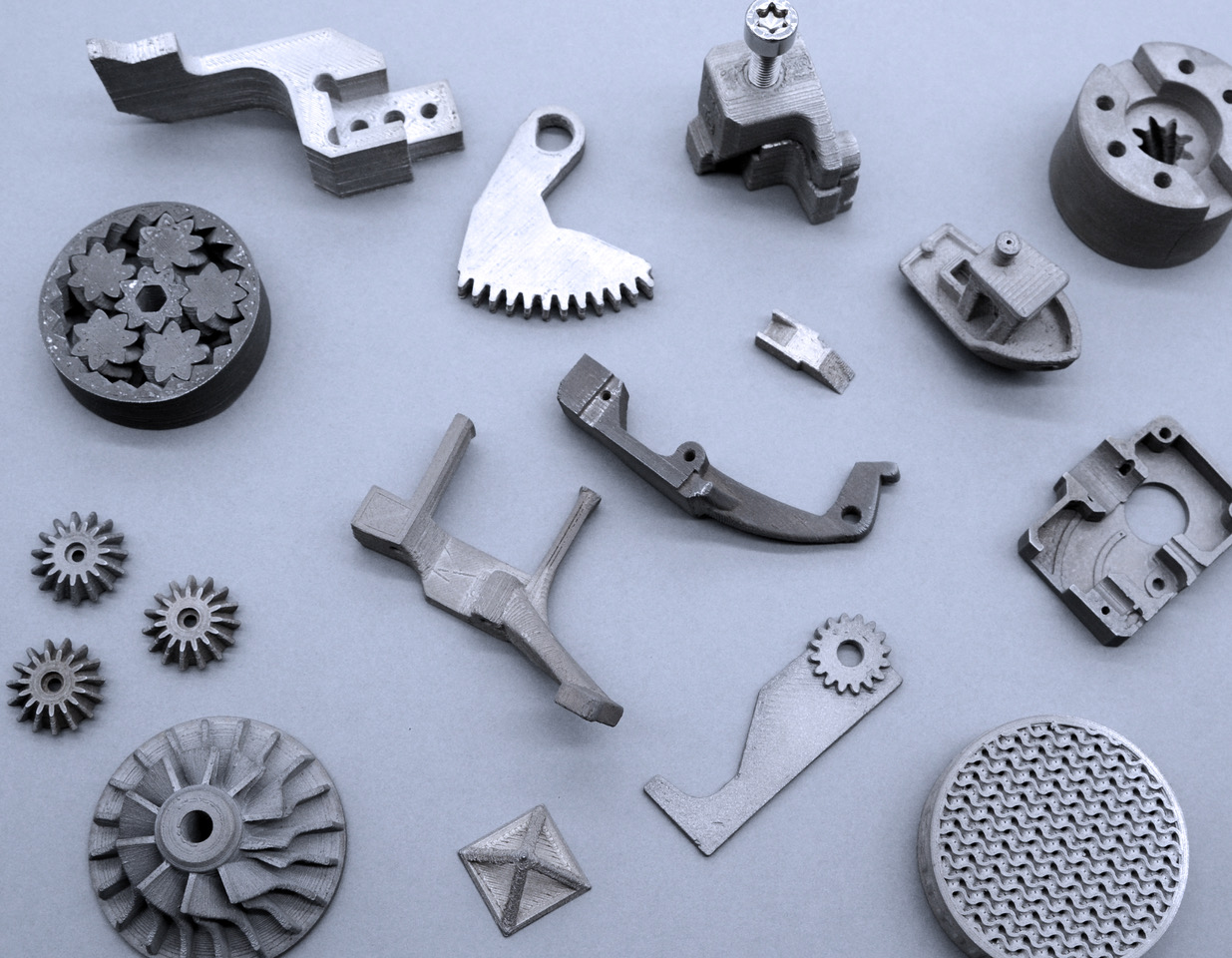

Zetamix has released a new version of its 316L stainless steel filament. The new product has been improved from its previous version, allowing an effortless production of parts with better dimensional accuracy. Thanks to this greater design freedom, Zetamix Stainless steel filaments’ users can print larger objects and parts with more important overhangs.

“Our philosophy is to offer a user-friendly system that sets us apart from the expensive and complicated options available in the market. Unlike other solutions that require post-processing by a service provider, our system enables users to easily print stainless steel in-house”. Guillaume de Calan, CEO

Furthermore, unlike the previous formulation that required sintering under pure hydrogen, resulting in the use of a specific type of furnace, this new filament has a much simpler post-processing method. To achieve a density greater than 90%, this new product must be chemically debinded and be thermally post-processed. This last step includes a thermal debinding and a sintering under 2.5% hydrogenated argon. Zetamix 316L can therefore be sintered under a wide variety of furnaces, including the Zetasinter furnace distributed by the Zetamix brand.

This development makes the filament more accessible to all laboratories and industries in need of 316L parts, but also makes it directly usable by the 100 laboratories, companies, and institutions already equipped with the Zetasinter furnace all over the world. Indeed, parts printed using the 316L Zetamix filament are already going through beta testing, including a helmet support for the Royal Dutch Navy and an industrial lubrication nozzle at MGB, a world leader in precision part machining.

Find out more about Nanoe at nanoe.com.

For more information about Zetamix, please visit zetamix.fr.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.