FQS Mechanical Engineering company (Italy), which is involved in engineering and manufacturing, was looking for an opportunity to speed up the process of molds creation for production of carbon fiber parts. Сarbon fiber parts are durable and reliable while being light in weight. In addition to their physical properties, they bear aesthetic value. For this purpose the company had already used laser systems, but wasn’t satisfied with the price-performance ratio and speed of work, so they decided to give a try to a white-light system. They chose RangeVision PRO 3D scanner as a more affordable alternative with a wide range of applications and an ability to capture complete surface of objects with high accuracy and speed.

For this purpose the company had already used laser systems, but wasn’t satisfied with the price-performance ratio and speed of work, so they decided to give a try to a white-light system. They chose RangeVision PRO 3D scanner as a more affordable alternative with a wide range of applications and an ability to capture complete surface of objects with high accuracy and speed. The task was to replace the side protection of BMW motorbike with the carbon fiber alternative. The original part was scanned in one day with the use of markers and matting spray. ScanCenter software, which comes with every RangeVision 3D scanner, allows fast and accurate merging of scans by markers, as well as getting a final model free of noise in .STL, .PLY and .OBJ formats.

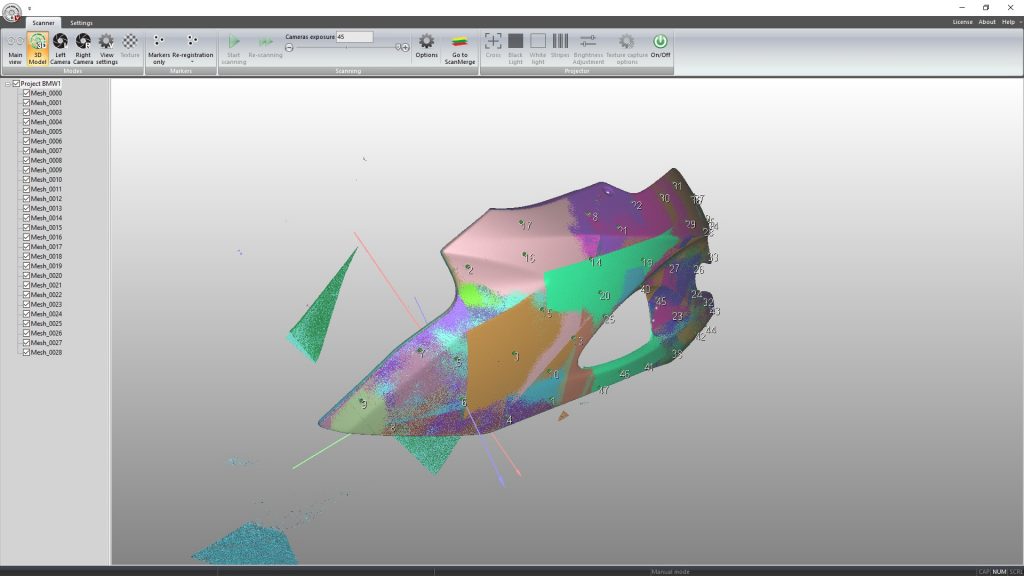

The task was to replace the side protection of BMW motorbike with the carbon fiber alternative. The original part was scanned in one day with the use of markers and matting spray. ScanCenter software, which comes with every RangeVision 3D scanner, allows fast and accurate merging of scans by markers, as well as getting a final model free of noise in .STL, .PLY and .OBJ formats.

Then, within a day, the final 3D model was transferred to casting aluminum molds, which will be used for the production of carbon fiber parts. In less than a week the company got complete molds for the part production. As a result the company has decided to buy RangeVision 3D scanner to use it on a regular basis.

With RangeVision 3D scanner the company managed both to save the budget and expand its production capabilities without loss of quality.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.