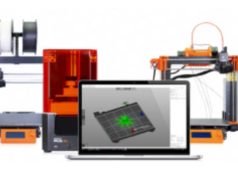

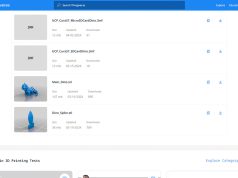

3D Systems has released version 13 of its Cimatron software for mold-, die- and tool-makers, with over 250 new features and enhancements for improved productivity and intuitive user experience.

Cimatron is part of 3D Systems’ end-to-end solutions and allows customers to optimise their processes and achieve higher productivity on the factory floor.

“Cimatron 13 eases the growing pressure tool shops are facing to stay competitive in quality and delivery time,” said Calvin Hur, Vice President, Co-Chief Operating Officer & Chief Revenue Officer, Software Products, 3D Systems. “This significant update provides the means for tool shops to create better tools and parts, faster.”

3D Systems has acquired the CAD/CAM specialist Cimatron in November 2014 to strengthen their 3D design portfolio.

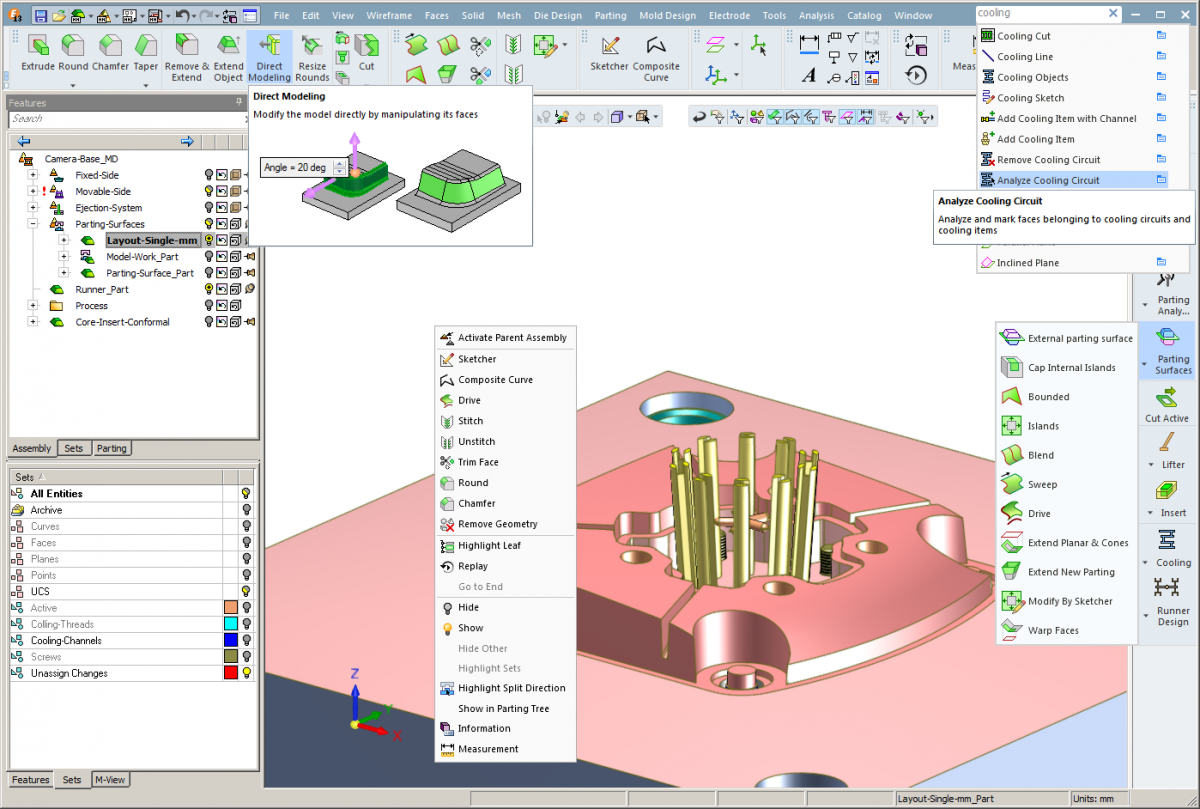

A fully redesigned user interface that is faster to use, and easier to learn and customizeCimatron 13 includes many new features and capabilities such as:

- A broad range of new CAD for tooling functionalities for faster design, including direct modeling, new mesh operations with hybrid modeling capabilities and enhanced assembly functions

- Boosted drafting capabilities including the dynamic creation of multiple views and the ability to create shaded views

- New mold-design applicative tools including gates design for a more streamlined design process and conformal cooling tools for the easy design of curved cooling channels that shorten injection cycle times and prevent part warpage

- Separate environments for progressive- and transfer-dies for quick design of any die type

- Smart electrode mirroring tools and hybrid design environments for accelerated electrode design with automated solid tools

- A new plate machining solution that provides a complete set of capabilities for fast, efficient and automated programming of mold- and die-plates

- New measurement on CNC machines to define the measurement probing cycle in the NC environment, allowing validation of the machining process while the part is on the machine

- New and improved NC programming capabilities for milling and drilling to boost programming automation in rough, finish and 2.5 axis operations

- Concurrent design and manufacturing environment, enabling multiple users to work on the same project simultaneously

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.