EOS, the technology and market leader for design-driven, integrated e-Manufacturing solutions for Additive Manufacturing (AM), will be presenting two new materials at this year’s EuroMold in hall 11, booth E148 – PrimePart® PLUS and PA 1101. Peter Klink, EVP Sales at EOS: “With these two new materials, EOS is extending its range of plastic materials clearly towards ecology, technical performance and low manufacturing costs, allowing standard components to be manufactured even more efficiently using laser-sintering.”

PrimePart PLUS (PA 2221): high performance combined with cost efficiency

The material PrimePart Plus (PA 2221) represents a breakthrough in polymer development. The material can evidently be refreshed using only a thirty per cent share of new powder, resulting in a powder cycle with minimum scrap quantities. This improves the cost efficiency and sustainability of the laser-sintering process, since conventional laser-sintering materials are usually refreshed using fifty per cent or more new powder. This does not lead to diminished technical performance of the material and the key performance indicators achieved are only slightly lower than those of PA 2200.

PA 1101: new polymer class made of renewing resources

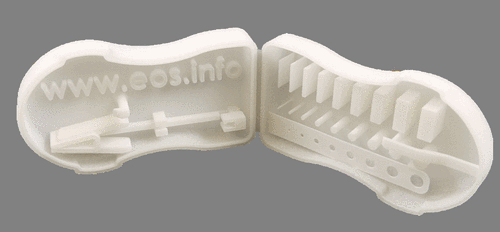

The PA 1101 material is a natural-colored polyamide 11 which is characterized by high elongation at break and impact resistance with a balanced performance profile. The material is based on renewing resources and can thus be classified positively in environmental terms. On account of its material properties, the material is particularly suitable for applications with functional elements which require high material ductility (e.g. integral hinges) and ones where high impact resistance is important. Another typical application for this material is for components which do not allow chipping (e.g. passenger cell in vehicles). Klink adds: “Our customers expect material solutions that support the ever widening range of applications in the best possible way. With PA 1101 we have been able to significantly extend our portfolio previously dominated by polyamide 12. We are looking forward to new and exciting applications which have not been possible with the materials available so far, or only by adapting the design accordingly.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.