Flexible filaments may be used for a number of applications: gadgets, functional prototypes or end parts. How they will be used depends on the needs of the designers. Recently, Fiberflex 40D has provided a solution for the young enthusiasts of aerospace from the AGH University of Science and Technology.

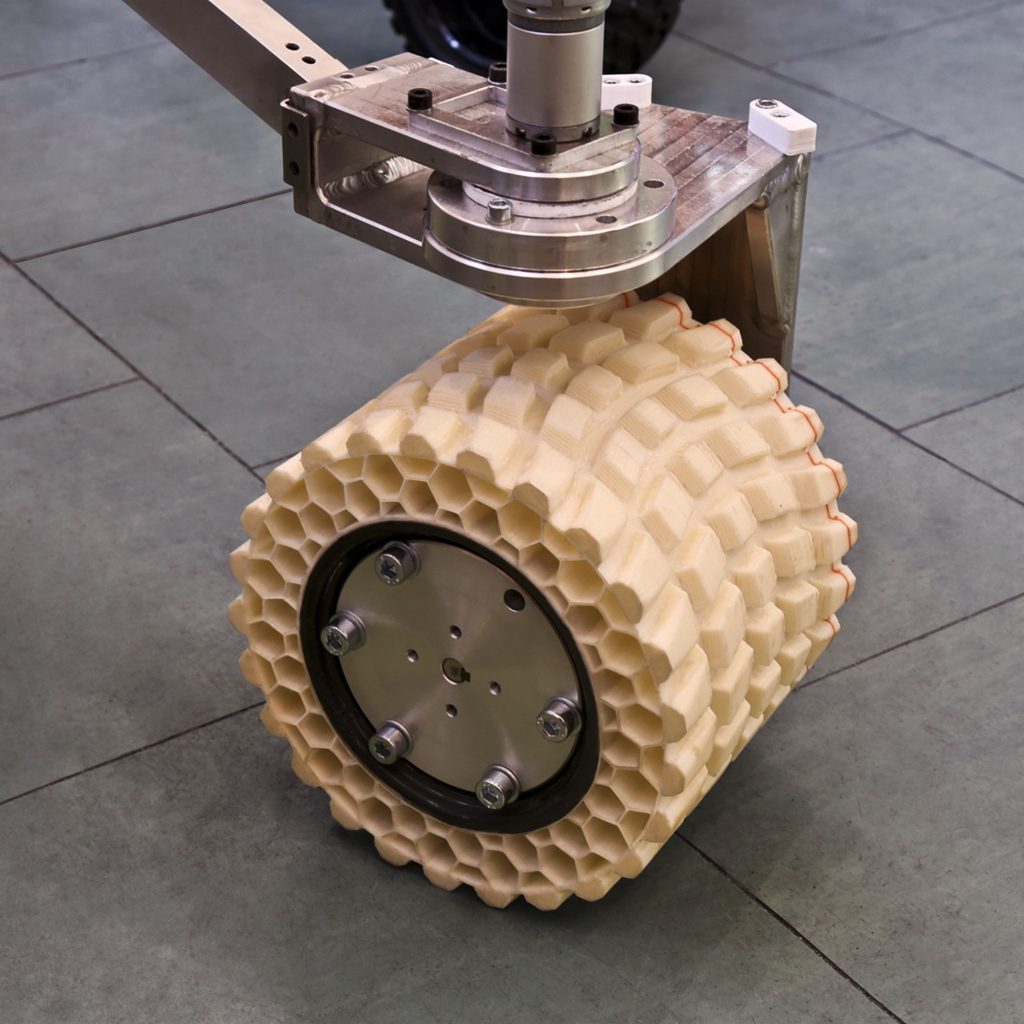

The students who belong to the Space Systems scientific club in Krakow have proved that Fiberflex 40D may also be useful in aerospace. They used the material to build the tyres of a Mars rover vehicle for University Rover Challenge and European Rover Challenge 2018 organized by NASA in Utah, USA and ESA in Rzeszow, Poland. 3D printing technology and Fiberflex 40D were all they ever required to meet the strict contest standards. The project was supported by a company Crystal Cave in the areas of generative design and 3d printing.

The whole idea came from Andrzej Zakręcki and Bartłomiej Gaczorek, who provided us with information for the purposes of this article. According to them, when designing a Mars rover it is important to take many factors into account, e.g. the weather conditions on the planet, temperature amplitudes, the structure of the ground and all the other elements of the environment. In this context, tyres call for special attention as they play a crucial role in the functionality of the vehicle.

The elements should meet the following requirements:

- The tyres should be of the appropriate weight, strength and stiffness.

- The tyre tread must be broad enough and its pattern should be similar to its off-road counterparts. Thanks to that it will be possible to ensure the necessary ground traction.

- Because of high temperature fluctuations that may cause expansion and contraction of parts, there is a need to find material resistant to this phenomenon

- Crucial parts of the vehicle should be protected against possible mechanical damages.

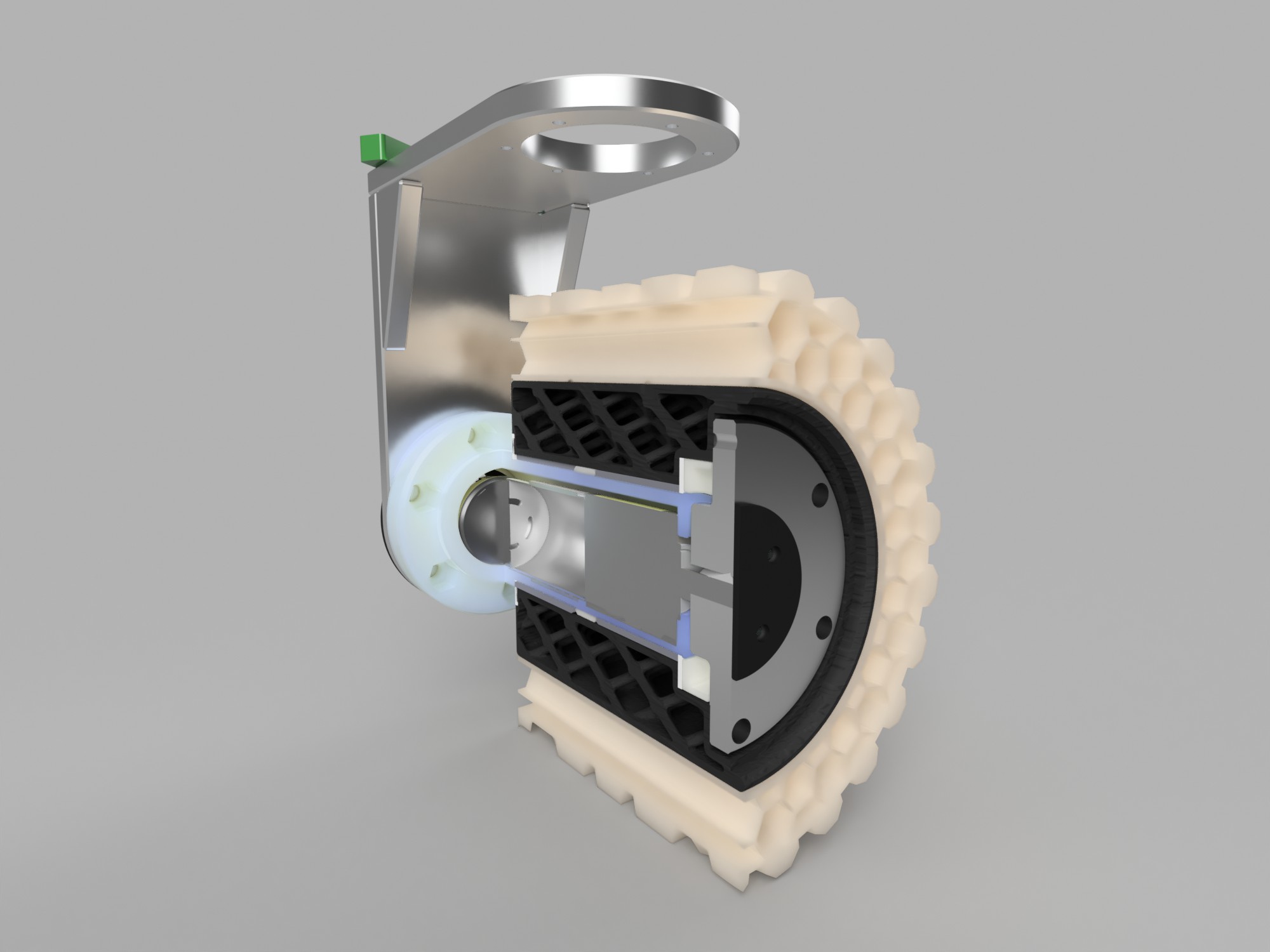

3d printing technology seemed to be a solution here. It was possible to adjust the weight of the tyre, its shape, hardness and stiffness. The custom design allowed for containing the propulsion system inside the wheel, which resulted in better protection of this part.

The properties of the material were also important. The filament resistance to temperature changes (from -40 to 70°C) made it possible to use it in the project. Moreover, its flexibility enabled better ground adhesion of the tyre.

As the young engineers admitted, they wouldn’t have achieved such results using traditional methods. Even if they did, it could have been expensive and time consuming. The benefits of 3d printing with Fiberflex 40D have only encouraged them to use this method in further projects.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.