The Polish branch of TI Fluid Systems, a global automotive supplier, uses selective laser sintering (SLS) to produce functional prototypes and spare parts.

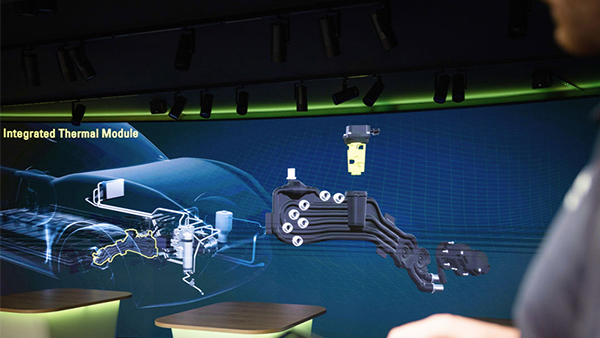

TI Fluid Systems is a manufacturer of fluid technology for the automotive industry headquartered in Oxford, England. With more than 100 years of experience and 28,000 employees in 29 countries, the company has established itself as a major supplier to the automotive industry. Primarily, TI Fluid Systems specializes in the design and production of industry-leading fluid transport systems and fuel tank and delivery systems, which are found in two-thirds of all vehicles worldwide.

One of TI Fluid Systems’ 114 offices is located in Bielsko-Biała, Poland, where Paweł Pułtorak has headed the engineering department for 18 years.

“3D printing is a very important tool for supporting the work of engineers in the design department”, states Pułtorak.

The team uses the Sintratec S2 SLS printer to validate their designs.

“The main use of the 3D prints is to verify the shape and geometry of the designed elements before making the injection mold and going into series production”, Pułtorak explains.

Due to the high demands placed on prototypes in the automotive sector, the company decided to invest in a Sintratec S2 – a selective laser sintering (SLS) system. Other technologies cannot be used to print such precise components, Pułtorak points out.

By using SLS and the robust Sintratec PA12 material, they reduce production costs and shorten time to market. They also print housings, structural and tooling elements, and spare parts.

“The SLS parts allow us to assess whether there are collisions in our assemblies”, explains the department head. “We also use them during our project group meetings and in functional tests.”

The precision and strength of the 3D-printed elements play a crucial role for the team.

“What we like the most about the Sintratec S2 system is the accuracy of 3D printed elements. The machine is definitely a good investment”, summarizes Paweł.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.