In 3D printing, filigree structures and overhangs can often only be realized with support material, which increases costs and reduces surface quality. Slant 3D explains in a YouTube video how such features can be designed without supports or with minimal support requirements.

According to the YouTuber, you should try to avoid support structures from the outset when designing for additive manufacturing, as these involve a lot of post-processing work. Small tabs, clips or openings in particular are often modeled with flat overhangs, which would not be printable without supports.

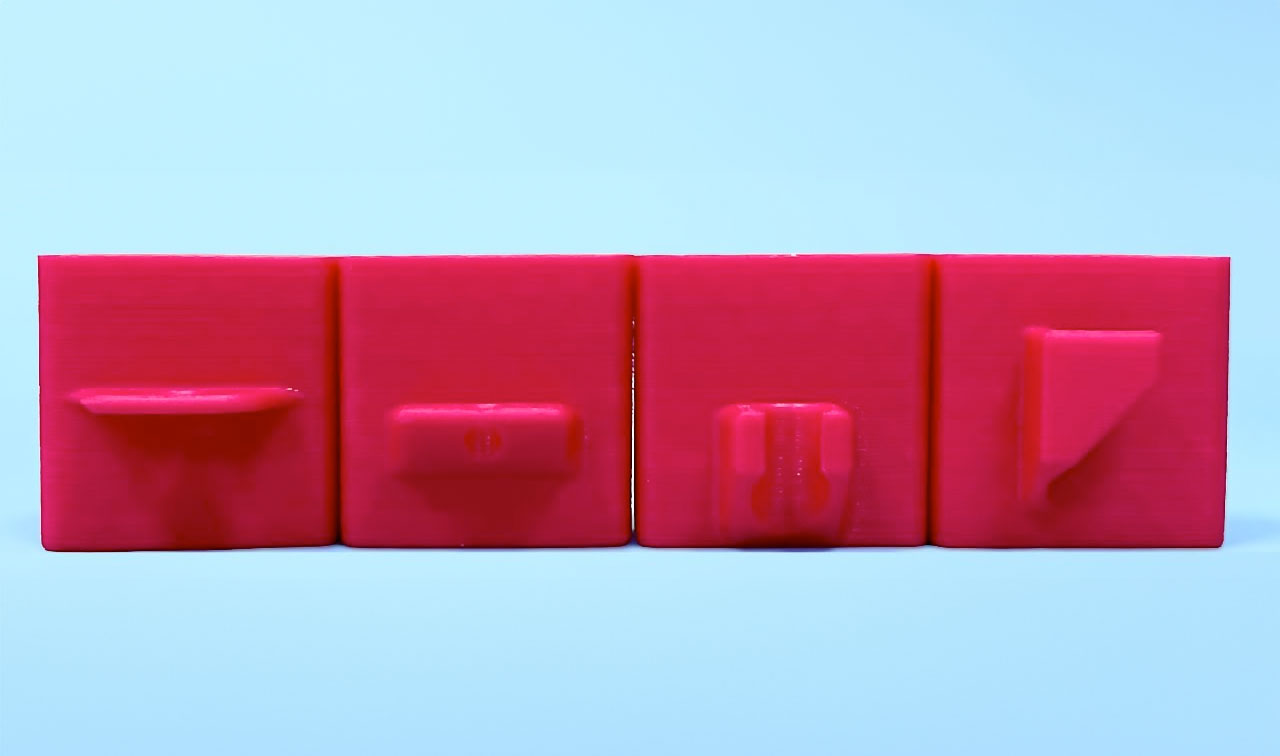

Instead, the expert recommends arranging such elements at an angle and chamfering the underside. In this way, the identical functionality can be realized without supports. For example, clips can also be designed to be elastic and snap into other parts.

The principle is also suitable for cable bushings or guides. Instead of simply allowing a loop to protrude horizontally, it should be bent twice at an angle. Wire can then be fixed just as securely without supporting structures impairing the print result visually or mechanically.

As the video shows, designers need to rethink 3D printing and optimize components from the ground up for layer-by-layer production – traditional overhangs are often suboptimal. However, clever modeling can create highly functional yet attractive products without support structures.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.