Luxexcel NV, a fast growing 3D print company that can print lenses and Automation and Robotics (A&R), the leading manufacturer of high-tech measurement equipment for optical labs, announce a technical collaboration on a quality control program to ensure that 3D printed lenses will meet industry and user requirements. The quality control program makes use of the Dual LensMapper manufactured by A&R.

3D printed ophthalmic lenses: quality control

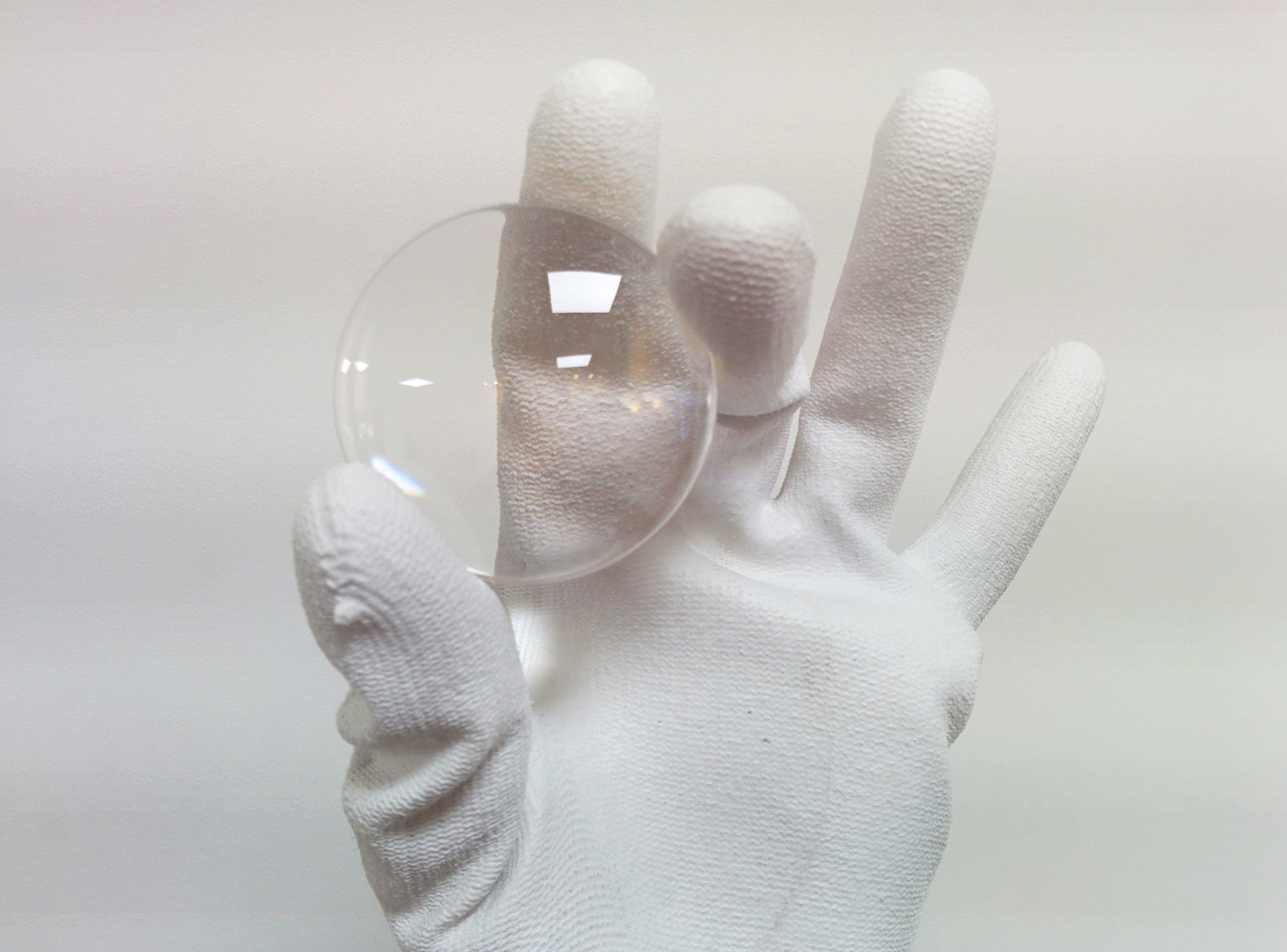

Luxexcel can 3D print lenses without polishing or grinding. Guido Groet, CMO Luxexcel states: “Together with A&R Automation and Robotics we have now started a quality control program which will allow us to assure that our 3D printed lenses will meet both industry and user requirements. Our continuous development efforts will bring us to imaging quality and we expect to be ready for certain applications in the course of 2017. The Dual LensMapper allows us to inspect the lenses in detail and take our quality control to the next level”.

Dr. Christian Laurent, R&D director at A&R comments that the A&R unique measurement technology as well as the lens quality and real time manufacturing process evaluation tools, developed for the free form manufacturing, fit particularly well to the needs of the 3D printing: “The accurate and high resolution optical power error map provided by the Dual LensMapper evaluates the ability of the digital 3D manufacturing method to replicate the expected theoretical design. In parallel, it is possible to demonstrate that this ‘through’ power error is related to the lens thickness local variations, the most important aspect of the additive manufacturing process to be controlled for providing good quality lenses.”

3D printing for the ophthalmic industry

3D printing has disrupted many industries by removing the requirements for identical products and allowing customization to individual needs. Currently, many different materials can be 3D printed for many applications, one of these applications are spectacle frames. The one elusive application has been optics, because of the requirements in transparency, surface smoothness and accuracy. 3D printing technology will provide significant advantages to both the ophthalmic industry and glasses wearers. It simplifies manufacturing processes, allows to create lenses for new frame shapes and enhances the freedom in lens designs. 3D printing also massively reduces the environmental impact of the existing lens manufacturing industry.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.