As additive manufacturing technology continues to advance, so does its application and accessibility. Rapid prototyping and tooling are at the forefront of 3D printing, but the goal has always been to be able to print directly for production or directly for manufacturing. The medical world is no exception. Although the first 3D printing applications in the medical field were prototyping and visualization guides, this technology has finally reached the stage of custom implants using state-of-the-art 3D printers.

With Eplus3D’s latest line of metal 3D printers, Eplus3D is drawing the attention of medical partners who are incredibly leveraging this technology. One of the pioneering partners in the creation and use of medical implants is MANTIZ.

MANTIZ is a medical device company that uses engineering and technology to achieve an active and painless life for all patients with spinal disorders. MANTIZ has obtained KFDA certification (medical device approval) and is listed on the HIRA (Health Insurance Review and Evaluation) list in South Korea.

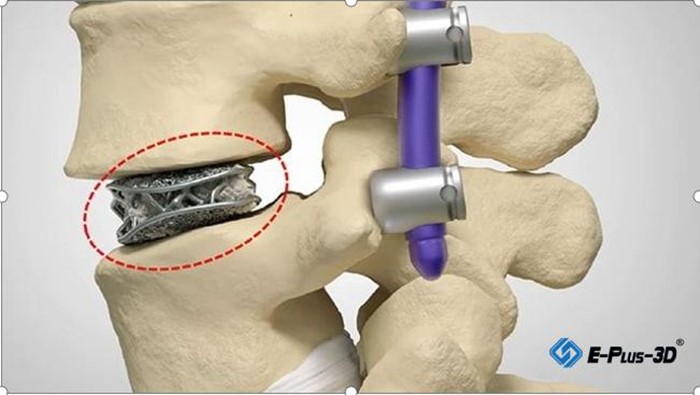

MANTIZ began developing 3D printed cage implants with government approval and funding. They launched a 3D printed PANTHER cage system for PLIF (Poster Lumbar Interbody fusion) / TLIF / OLIF / ALIF surgery. This process uses 3D printed cage implants without outsourcing the manufacturing process to a third party. This saves customers time and money and reduces the chance of production errors.

Advantage of Titanium 3D Printed Cage:

PANTHER has been formulated to optimize bone growth during spinal procedures, with an average pore size range of 630-730μm in the contact surface of the spinal end plates and an average porosity of the mesh section in the range of 70% -80%.

MANTIZ uses Eplus3D’s EP-M260 metallic 3D printer to manufacture cages printed in titanium 3D for use in implant surgery. The entire process of shaping the implant is done internally by MANTIZ. The cage is designed according to specifications. Size, material, shape and porosity are essential to the effectiveness of the implant. The complete design of the cage is loaded into the printer software, where it is ready for printing.

The large print bed of EP-M260 can be used to print more than 50 individual implants in one structure. Upon transplantation, the bone and surrounding tissue begin to fuse with the implant, creating a strong structure in the patient’s spine.

Hongwon Yoon (CTO of MANTIZ) the inventor of MANTIZ’s PANTHER 3D print cage system, said: “We have completed the development of a more improved titanium 3D printed cage implant using the EP-M260 3D metal printer. Mechanical test results prove the safety and functionality of the implant. 3D printing the average closed pore ratio of the solid titanium component is 3%, which promotes the binding of the protein for bone fusion to the mesenchymal stem cells.”

For more information about EPlus3D, please visit www.eplus3d.com, or contact Eplus3D directly (info@eplus3d.com).

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.