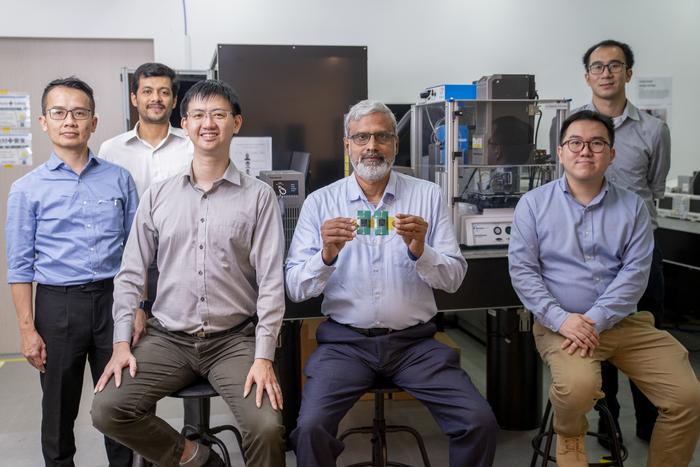

Researchers from Nanyang Technological University in Singapore (NTU Singapore), Panasonic Factory Solutions Asia Pacific Pte. Ltd. (Panasonic) and the Singapore Centre for 3D Printing (SC3DP) have developed a multi-material 3D printer. This uses high-powered lasers with different wavelengths to print smart, flexible parts quickly and easily.

The printer’s technology is based on the use of different laser wavelengths that generate thermal and chemical reactions. These reactions are capable of transforming everyday carbon-based materials such as polyimide and graphene oxide into a new type of highly porous graphene. The resulting graphene is not only lightweight and conductive, but can also be printed or coated onto flexible substrates such as plastics, glass, gold and fabrics. This creates flexible parts.

Traditionally, electronic products and components are made of rigid materials such as metals, silicon and ceramics. But recently, there has been growing interest in creating flexible, wearable electronics that can be bent, twisted and easily adapted to different surfaces.

The newly developed 3D printing technology has already attracted the interest of several companies, such as JABIL-MTI Penang. This manufacturer plans to integrate 3D-printed graphene-based electronics into a smart infusion system. A prototype of a low-cost intravenous fluid bag with an embedded printed sensor powered by artificial intelligence has already been unveiled.

The NTU and Panasonic team believes that the newly created multi-material 3D printer offers a level of flexibility and functionality unmatched by other similar products on the market. They believe this innovation has the potential to transform the field of 3D printing and open up new possibilities for product designs.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.