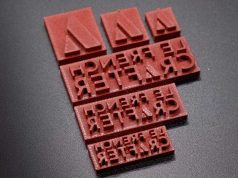

A new seam technology called “Scarf Seam” promises to significantly improve the surface quality of 3D prints. In additive manufacturing using the FDM process, models are created by applying plastic layer by layer. At the points where a layer begins and ends, visible seams are created that often impair the appearance.

The Scarf Seam technique is designed to solve this problem by creating diagonal transitions between the layers. Michael from Teaching Tech shows this in a YouTube video. Developers of the open source software Orca Slicer are expected to implement an initial version based on suggestions from the community. As tests have shown, the seams become almost invisible when the function is activated for both round and square models.

However, the effect still depends on numerous settings. Extensive test series were carried out to determine the best parameters. According to the results, “Scarf Seam” has a particularly positive effect on smooth surfaces. On models with overhangs, the seams remain partially visible.

Nevertheless, the technology represents a major step forward, as it noticeably improves the print quality in many applications. In the future, it could also be adopted by other slicing programs. PrusaSlicer is already making developments in this direction. Printables also has a guide to “Scarf Seam” for Orca Slicer.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.