UltiMaker PET Carbon Fiber is easy to handle and versatile, suitable for a wide range of applications from functional prototypes to manufacturing aids and spare parts.

It also serves as a reliable solution for manufacturing spare parts, avoiding costly production downtime.

A highlight of PET CF is its annealing resistance, which can be increased up to 181 °C by annealing. This increases strength by up to 30% and stiffness by up to 10%.

“We are thrilled to introduce the UltiMaker PET CF, UltiMaker’s first composite material that has been optimized for UltiMaker S series printers,” said Nadav Goshen, CEO at UltiMaker. “PET CF’s ability to achieve higher strength and temperature resistance through annealing sets it apart from other materials, while its versatility allows engineers to use it for a number of applications. The material represents a significant advancement in our portfolio and reinforces our commitment to delivering cutting-edge solutions.”

PET CF is resistant to moisture and requires little drying. When stored in the UltiMaker Material Station, it remains well conditioned. In addition, PET CF is available in a variety of colors, providing an additional feature to customize for specific applications.

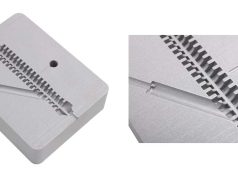

For users who want a complete solution, PET CF will be available as part of the UltiMaker PET CF Expansion Kit. This includes PET CF spools in different colors and special print cores.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.