Orbital Composites, a pioneer in additive manufacturing for space, secures an SBIR grant from the U.S. Space Force. The focus is on developing 3D printable quantum antennas that could set new standards in secure space communications.

The innovation comes at a time when the need for new ground station antennas is increasing, driven by satellite constellations and telecommunications projects. Orbital Composites combines quantum principles with 3D printing technologies to set new standards in the industry.

“Orbital approach to antennas represents a quantum leap in functionality,” said Cole Nielsen, Founder and CTO of Orbital Composites. “With >100x cost reduction, our Quantum Antennas will enable global scale broadband and clean energy.”

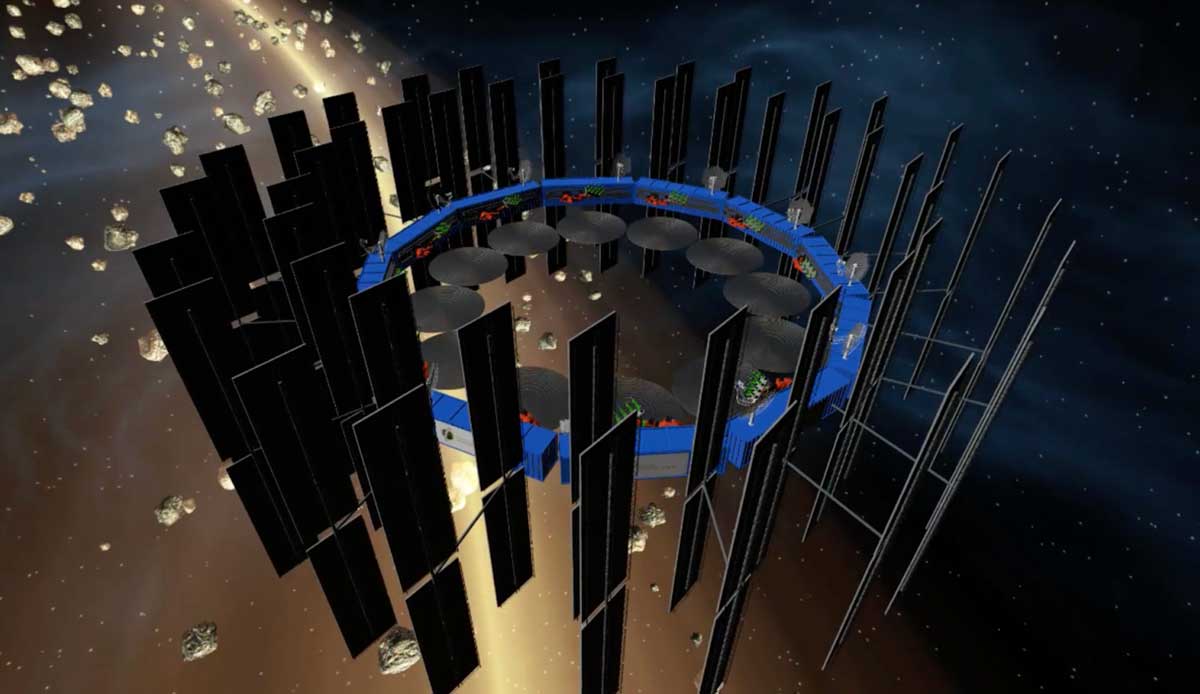

However, the company plans to use its technology for more than just Earth. Using In-Space Servicing, Assembly, and Manufacturing (ISAM) could create much larger space antennas that bypass the limitations of rockets and payload fairings.

“With LEO constellations propping up everywhere, we already have a big bottleneck facing ground stations,” said Amolak Badesha, Co-founder and CEO of Orbital Composites. “This technology promises to relieve these bottlenecks, and eventually, pave the way for making giant antennas on orbit, for applications like space-based solar and direct-to-cell broadband.”

In addition to the SBIR contract for the quantum, Orbital Composites has been awarded a total of three such contracts and previously won a direct-to-phase II grant of $1.7 million. Total government contracts exceed $6.5 million. Partners include Axiom Space, Northrop Grumman and Southwest Research Institute.

The award of the SBIR contract to Orbital Composites underscores the growing interest in innovative communications technologies for space. The combination of 3D printing and quantum technology could dramatically reduce costs while increasing the performance of antenna systems. These developments could significantly impact the trajectory of the space antenna market and enable new use cases in the space economy.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.