Researchers at Georgia Tech University have made a breakthrough in 3D printing glass. With the help of UV light, they can harden structures made of silicon dioxide at just 220 degrees Celsius. Previously, temperatures of over 1000 degrees were necessary.

According to Professor Jerry Qi, the process opens up new possibilities for microcomponents made of glass, such as lenses or lab-on-a-chip systems. Instead of plastics, a light-sensitive resin is used that vitrifies through UV treatment.

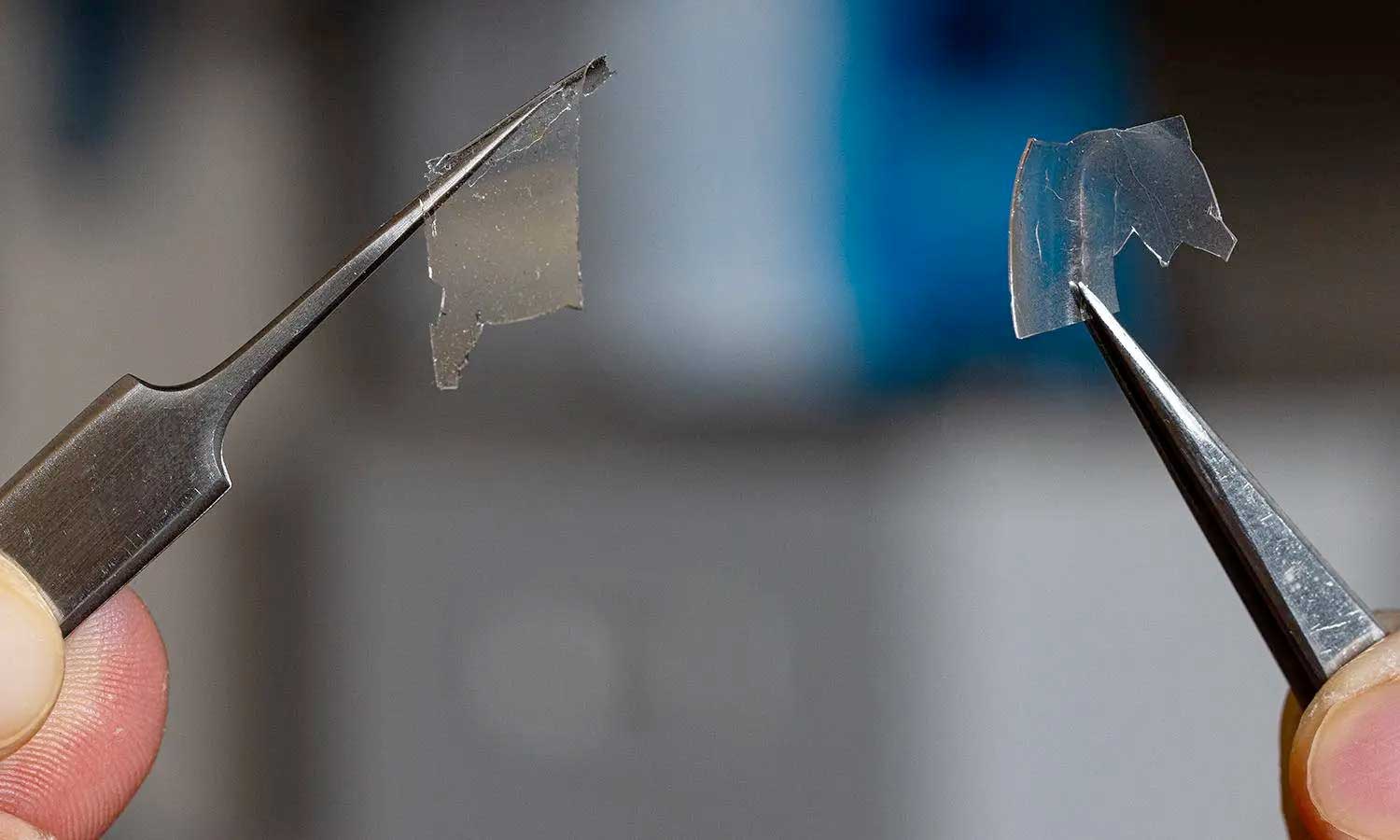

In addition to saving energy compared to conventional glass 3D printing processes, the approach scores with better transparency and surface quality. In addition, electronic circuits can be printed directly because the low temperatures do not cause any damage.

With the scalable method, the research team hopes to open 3D printing to new application areas such as medical technology, microfluidics and microelectronics. According to Qi, the Navy as a sponsor specifically encouraged research into new approaches to low-temperature glazing.

More on the research can be found in the paper “Low-temperature 3D printing of transparent silica glass microstructures” which appeared in the journal Science Advances.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.