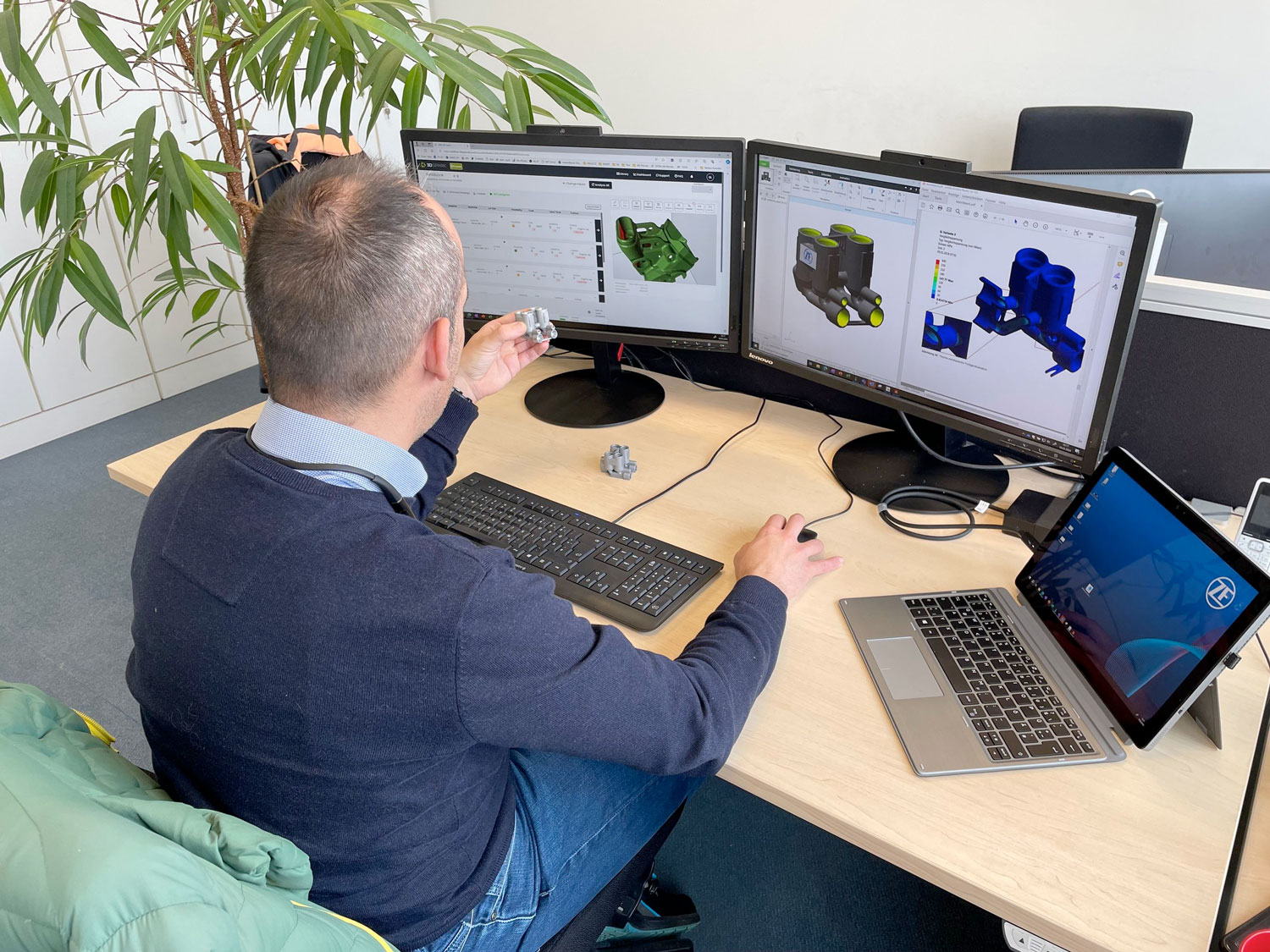

Automotive supplier ZF has introduced a new software solution for digital manufacturing. The company is using the cloud-based B2B platform 3D Spark to simplify the process of ordering parts for 3D printing.

ZF is pursuing several goals with the use of additive manufacturing. In addition to shorter lead times for prototypes, tools and spare parts, the Group expects cost savings, greater supply chain resilience and a reduction in CO2 emissions.

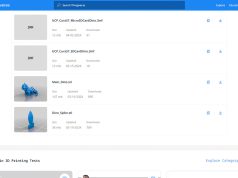

The 3D Spark platform offers an integrated approach for the entire workflow – from parts order request to quotation. Users gain insight into design suitability, manufacturing capabilities, optimization potential, costing and carbon footprint for each production option. This includes 3D printing for polymers, metals and ceramics as well as conventional processes such as milling, turning, casting and injection molding.

Increased efficiency and accuracy

By using 3D Spark, ZF has been able to reduce the time required for production analysis and quotation preparation by 50 percent. At the same time, accuracy and reliability increased by 25 percent.

“The self-service solution can be used by every employee, not just AM experts. In this way, we are making cutting-edge technology accessible to everyone,” says Dr Ignacio Lobo-Casanova, Head of Lightweight Technologies at ZF, explaining the democratizing effect.

His colleague Marcel Ahlbrand, Head of Chassis Component Development, adds: “With 3D Spark, we give our engineers the opportunity to check the costs and manufacturability of their components themselves, without having to involve experts.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.