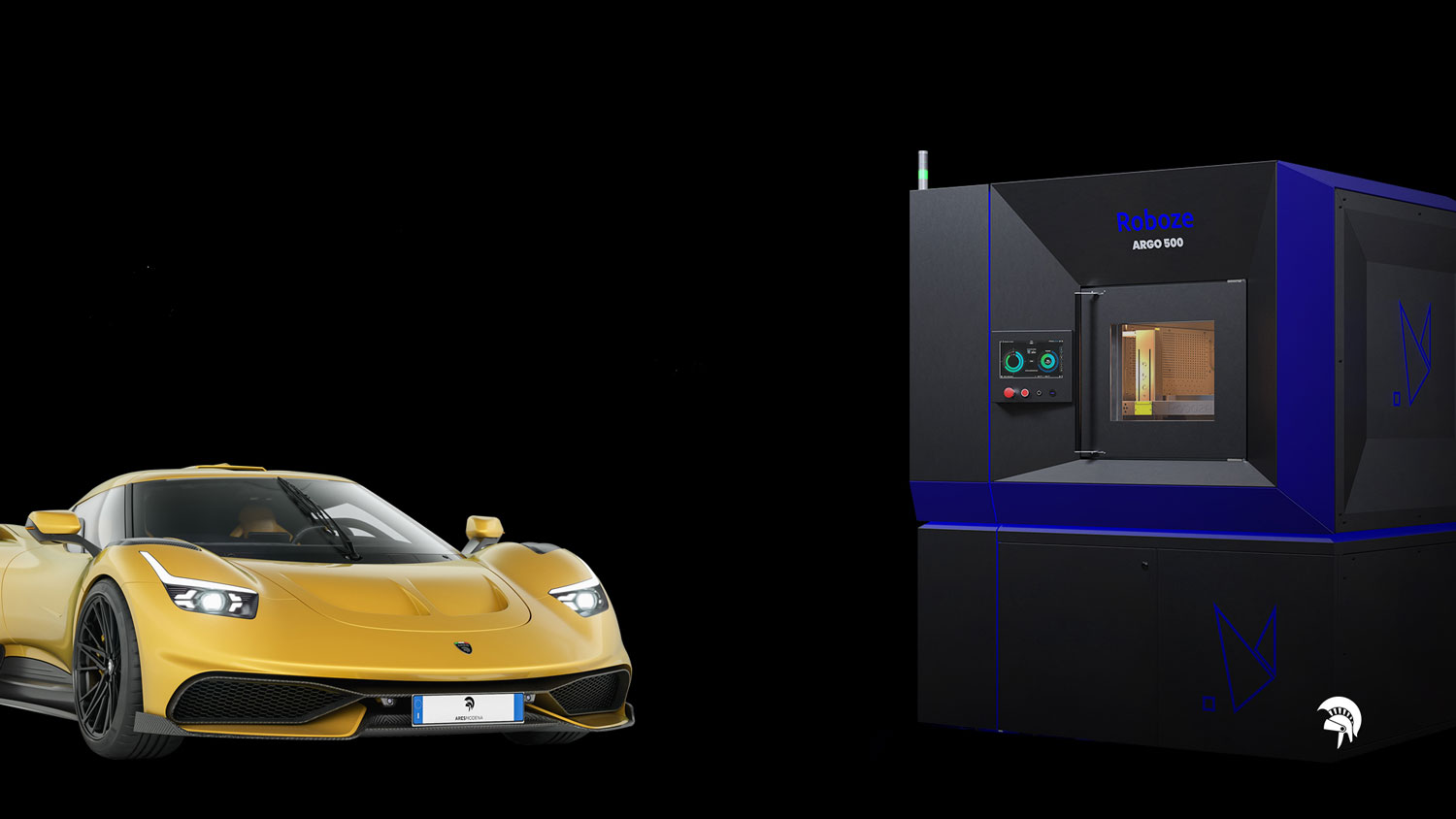

ARES Modena, a luxury carmaker dedicated to the design and production of one-off or limited edition cars and motorcycles, announced that it is turning to industrial 3D printing technology from Roboze for production.

ARES Modena, in the heart of Italy’s Motor Valley, realizes the dreams and visions of enthusiasts by creating unique and unparalleled vehicles that are impossible to obtain elsewhere. The company is capable of producing true bespoke road jewels, designed and produced to order. To increase its customization capacity and optimize its production processes, it implements Roboze’s ARGO 500 solution, a flexible additive manufacturing system for large, high-performance parts, at its modern 23,000 m² facility in Modena, which opened in January 2018.

“We chose Roboze for their industrial approach in 3D printing and their deep knowledge in materials science” declares Alberto Migliorini, Head of Technologies and Production of ARES Modena. “We are convinced that thanks to this solution we will further raise our level of design, development and production”.

As a result of crucial changes in the automotive world, with a strong and growing desire for individual solutions, flexibility and tailored customization, integrating an additive manufacturing solution such as Roboze’s can become strategic and accelerate innovation and new productivity frontiers. Indeed, Roboze designs and manufactures industrial 3D printers that are helping manufacturing companies around the world solve common problems related to process repeatability, precision, and the production of custom parts with high-performance polymers and materials.

“ARES creates unique and highly prestigious vehicles. ARES customers want the best performance ever” says Alessio Lorusso, Founder & CEO of Roboze. “At Roboze we have always had the goal of creating solutions that allow us to overcome current and future industrial challenges, using technology and science to solve complex problems. With ARES, we are convinced that all this can have free space, accelerating innovation and increasing the application opportunities of industrial 3D printing with high-performance materials, opening new paths for the manufacturing of the future”.

The union of the two Italian excellences expresses the maximum values of traditional craftsmanship combined with those of cutting-edge production techniques.

Find out more about Roboze at roboze.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.