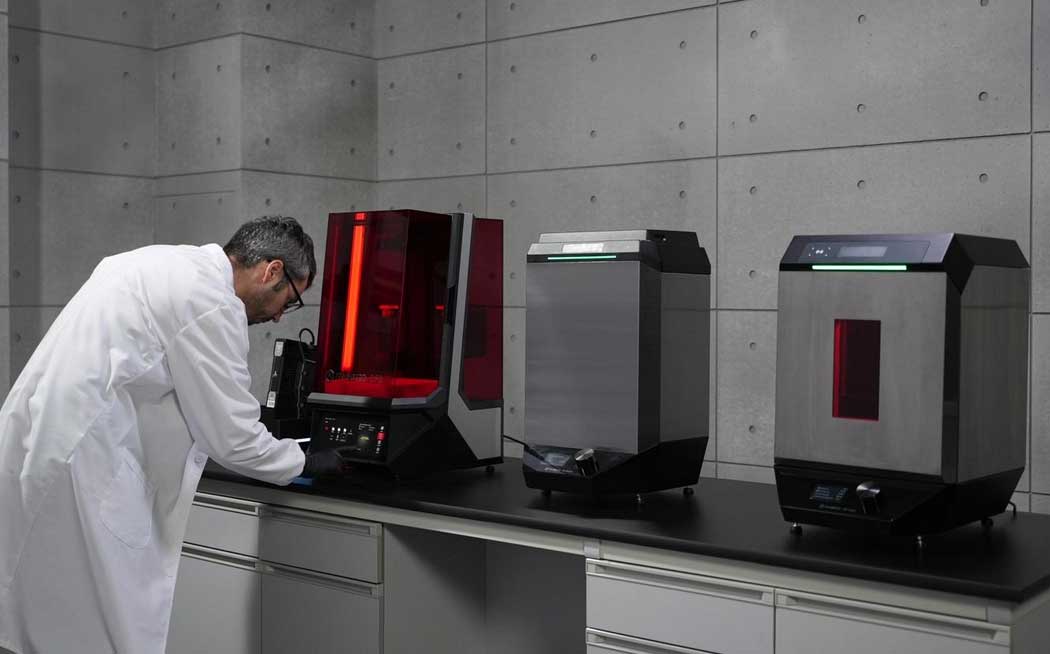

3D printer manufacturer Raise3D is expanding its portfolio with a solution for stereolithographic resin processing. The new DF2 series based on Digital Light Processing (DLP) technology has been specially developed for professional use in manufacturing, according to the company.

According to the announcement, the DF2 impresses with its high printing speeds and clean surface quality. Raise3D sees the solution as particularly suitable for the construction of prototypes, tools and small series. The printer is offered together with peripheral components for post-processing such as a washing and curing station.

Raise3D has also developed its own resins for the DF2, which are designed for high-temperature use and high strength. According to CEO Edward Feng, the aim of the solution is to make resin technology suitable for professional use in manufacturing. The focus is on simple operation and maximum quality and reliability.

Raise3D also emphasizes the open material strategy as an advantage. The company is working with partners such as Henkel and BASF to enable a large selection of resins. According to the announcement, the DF2 will be delivered from the first quarter of 2024. With the DLP solution, Raise3D is expanding its product portfolio as a manufacturer that previously specialized in FFF printing.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.