In the latest video on the YouTube channel “Let’s Print“, 3D-printed compressors are put to the test. The YouTuber has already experimented with a self-designed axial compressor in the past. The result was sobering: the 3D printed prototype turned out to be completely non-functional.

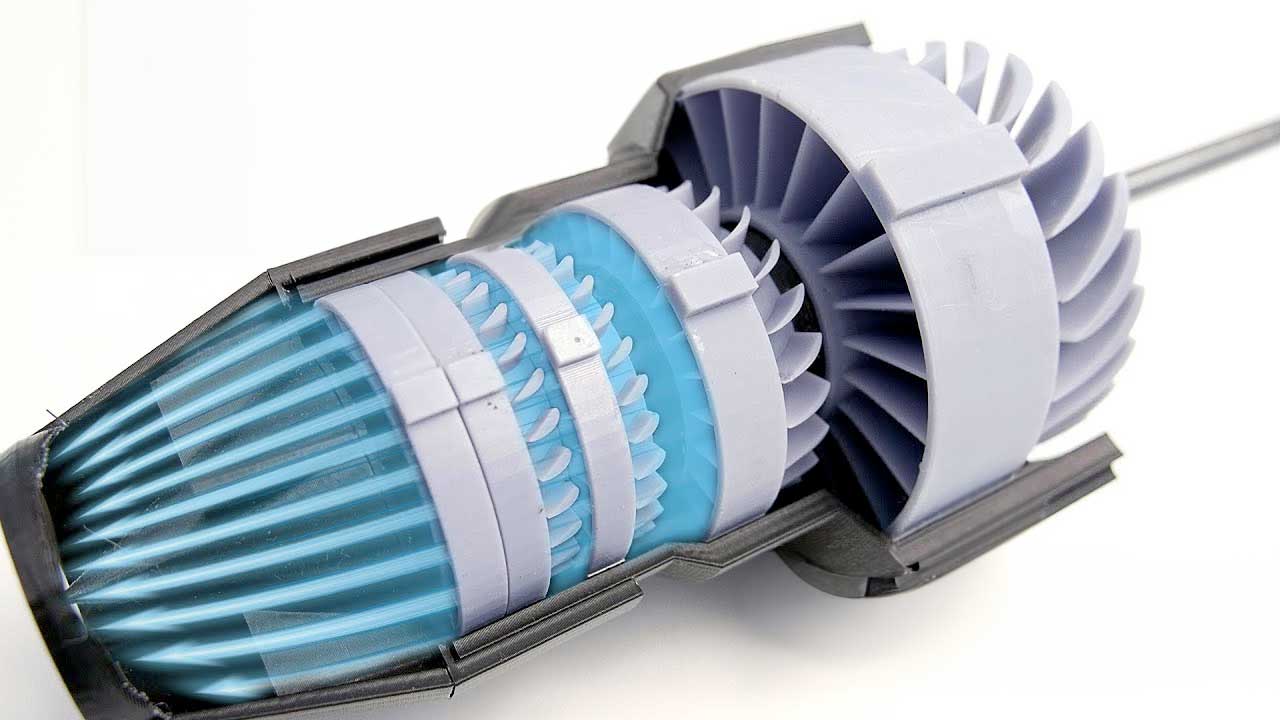

Driven by this failure, the inventor took on a new design. This time, he used a 5-stage axial compressor that he had found on the internet. He also designed a dual centrifugal compressor, in which two compressors are connected in series.

The YouTuber printed both models using a resin printer. He then put the designs together and tested them. And indeed: both the new axial compressor and the centrifugal compressor were able to compress air. The axial compressor managed to inflate plastic bags. However, the hope of bursting a balloon with the compressors was not fulfilled.

According to the YouTuber, the problem lies less in the compressor’s performance and more in the durability of the components. The housing and impellers of the centrifugal compressor wore out quickly, meaning that it was only functional for a short time. The axial compressor proved to be more durable, but did not achieve maximum performance.

Instructions for the axial compressor can be found here.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.