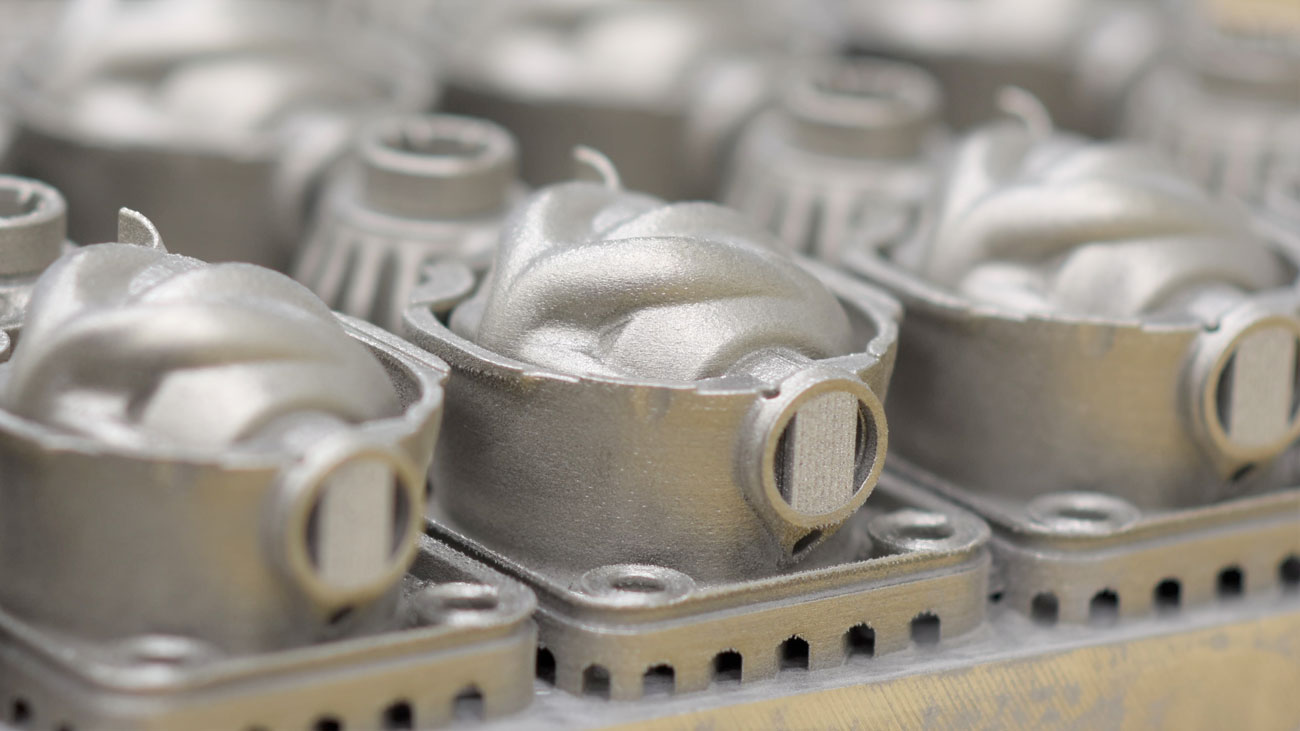

UK manufacturer Renishaw has announced that it has supplied one of its RenAM 500Q additive manufacturing systems to fluid power specialist Domin. Domin will use the 3D printer to design and manufacture a range of servo-proportional hydraulic valves.

Domin has developed the new range of high-performance hydraulic valves to meet the stringent requirements of control systems in industries such as automotive, aerospace and manufacturing. Domin will manufacture the valves using Renishaw’s RenAM 500Q system at its new technology center in Pucklechurch, near Bristol, where the company is consolidating manufacturing from one Polish and two UK sites.

“We designed these servo valves to achieve a better-performing, more sustainable product at a lower price point,” said Domin CEO Marcus Pont. “The success of these valves in a broad range of applications means demand is outpacing what we can supply. Renishaw is the go-to choice for coupling productivity with quality, and we expect that the increased capacity the new AM system provides will allow us to maintain low production turnaround times and deliver consistently high quality to our growing customer base.”

“With four high-power 500W lasers able to access the whole powder bed surface simultaneously, the RenAM 500Q system achieves significantly higher build rates than previous systems, which vastly improves productivity and lowers cost per part,” said Bryan Austin, Director of AM Sales at Renishaw. “This productivity enabled Domin to take its range to market competitively. Their valves require high precision machining to achieve tight tolerances and accurate positioning, and use high-grade materials to ensure strong chip shear and durability. Domin wants to manufacture them at scale and our RenAM 500Q system makes meeting these requirements possible.”

The hydraulic valves are manufactured at Domin’s new technology center in Pucklechurch, near Bristol, using Renishaw’s RenAM 500Q system. The valves meet the stringent requirements of control systems in diverse industries such as automotive, aerospace and manufacturing.

“Most hydraulic systems today only operate at 23 per cent efficiency, resulting in the wastage of billions of kilowatt-hours every year,” said Pont. “Globally, hydraulics produces twice the CO2e emissions of the aerospace industry (1). Over its lifetime, each of these game-changing valves has the potential to save multiple tonnes of CO2e, and with them we can spearhead the advance of the fluid power industry towards a sustainable future.”

Austin concluded, “Domin is a great example of cutting-edge British engineering, and exactly the kind of innovator that’s going to help ameliorate the climate crisis. These high-performance valves show how additive manufacturing is increasingly suitable for high-spec, high production applications where it was previously uneconomic.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.