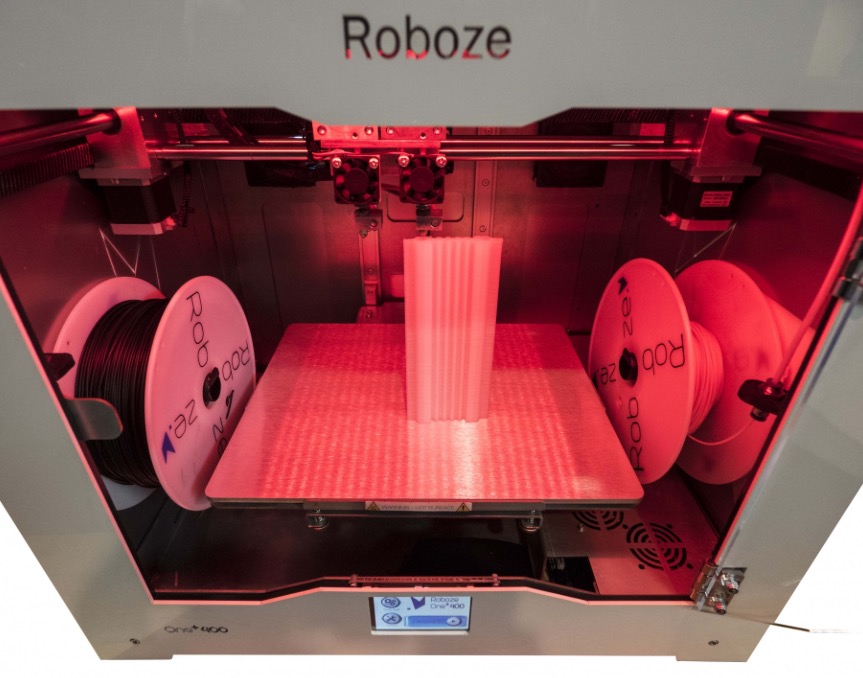

Italian 3D printer manufacturer Roboze will showcase the updated version of their prosumer 3D printer at the RapidPro, taking place in the Netherlands from March 1 to 3, 2016.

Based on its predecessor released last year, the Roboze One + 400 features a patented mechatronic movement system without belts, which is more accurate and works as fast as standard belt based movement systems. The new device is equipped with two extruders that can reach temperatures of up to 400°C and are therefore able to print material such as PEEK, PEI or PC. According to Roboze the printer is able to manage a total of 12 different polymers.

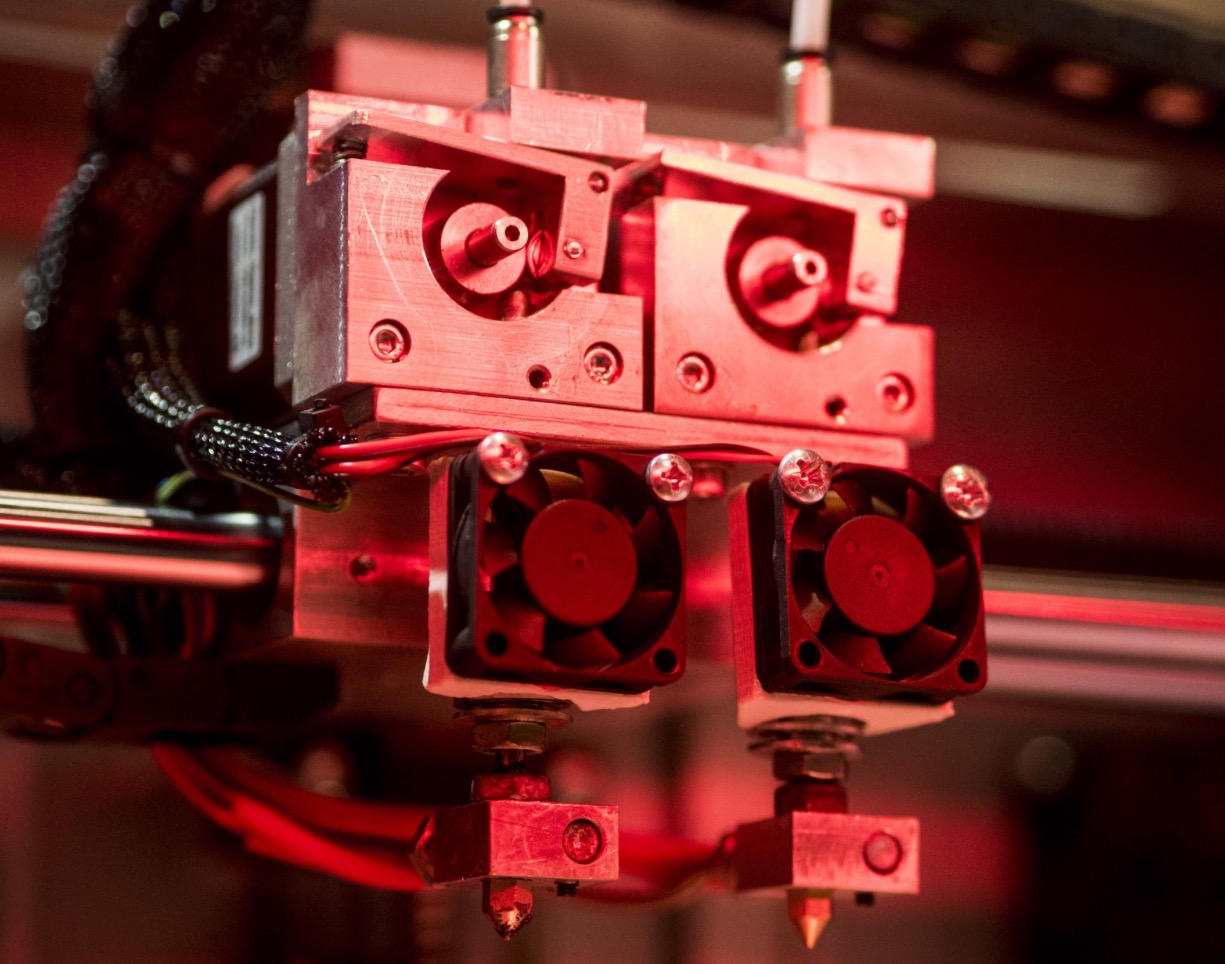

The extruders have been completely re-engineered by the company’s R&D team and are optimised for heat dissipation and for maintaining a controlled temperature. They were designed according to thermodynamics and material engineering, using aluminium for areas that need heat conduction and stainless steel for areas of heat dissipation.

The Roboze 3D printer is equipped with proprietary firmware. It can be controlled via an easy-to-use and intuitive 3.5″ touch screen.

Technical specifications:

- Build area: 200 x 200 x 200 mm

- Extruder: dual extruder, up to 400°C

- Build plate: heated, up to 150°C

- Resolution: 50 microns on X and Y-axes

- Materials: PEEK, NYlon 12, Polycarbonate, PC/ABS, TPU,PEI, flexible

- Filament: 1,75 mm

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.